Alternatives Cycles

Introduction

Traditional internal combustion engines predominantly use the Otto cycle or the Diesel cycle. However, various alternative engine cycles have been developed to improve efficiency, reduce emissions, and enhance performance. This chapter explores several notable alternative cycles, their operational principles, and their advantages and challenges.

The Otto Cycle

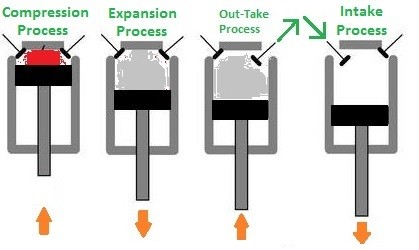

Before diving into alternative cycles, it’s essential to understand the conventional Otto cycle, which is the basis for most gasoline engines. The Otto cycle consists of four strokes: intake, compression, power, and exhaust.

Key Features:

- Fuel Type: Gasoline

- Operation: Spark-ignition

- Efficiency: Moderate, limited by thermodynamic constraints

Alternative Engine Cycles

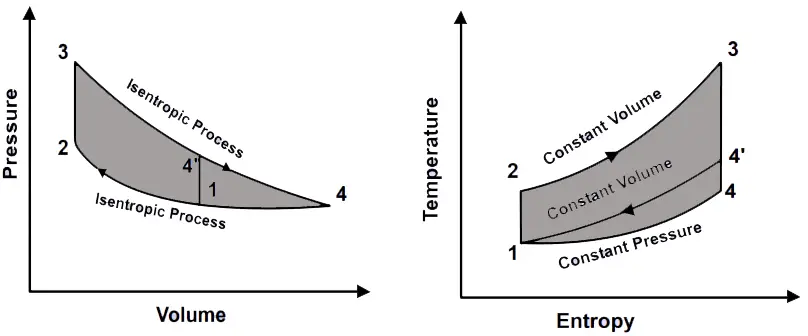

1. Atkinson Cycle

The Atkinson cycle is designed to improve the efficiency of the engine by increasing the expansion ratio relative to the compression ratio. This results in a more efficient power stroke compared to the Otto cycle.

Figure : Atkinson Cycle Diagram

Key Features:

- Fuel Type: Gasoline

- Operation: Spark-ignition

- Efficiency: Higher thermal efficiency than the Otto cycle

- Advantages: Better fuel economy and reduced emissions

- Challenges: Lower power output compared to Otto cycle engines

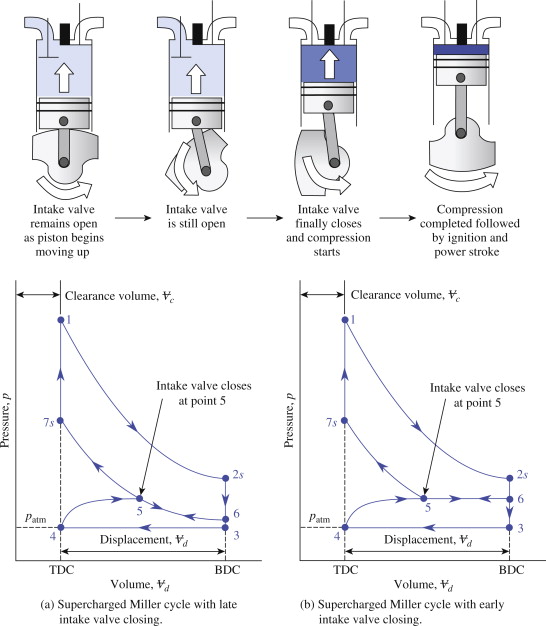

2. Miller Cycle

The Miller cycle is similar to the Atkinson cycle but incorporates supercharging to compensate for the loss of power efficiency. It modifies the intake timing to improve the overall engine efficiency.

Figure: Miller Cycle Diagram

Key Features:

- Fuel Type: Gasoline or Diesel

- Operation: Spark-ignition or compression-ignition

- Efficiency: Improved efficiency with forced induction

- Advantages: Better performance and fuel efficiency

- Challenges: Increased complexity and cost

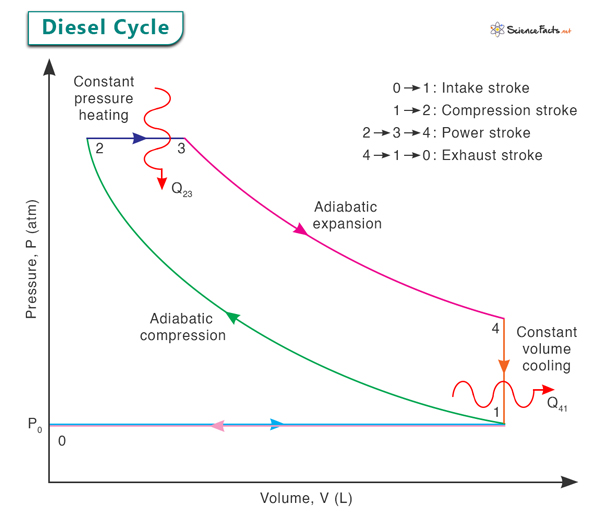

3. Diesel Cycle

The Diesel cycle, used in diesel engines, relies on compression ignition rather than spark ignition. It is characterized by higher compression ratios and greater efficiency compared to Otto cycle engines.

Figure: Diesel Cycle Diagram

Key Features:

- Fuel Type: Diesel

- Operation: Compression-ignition

- Efficiency: Higher thermal efficiency and torque

- Advantages: Better fuel economy and higher torque

- Challenges: Higher NOx and particulate emissions, noise

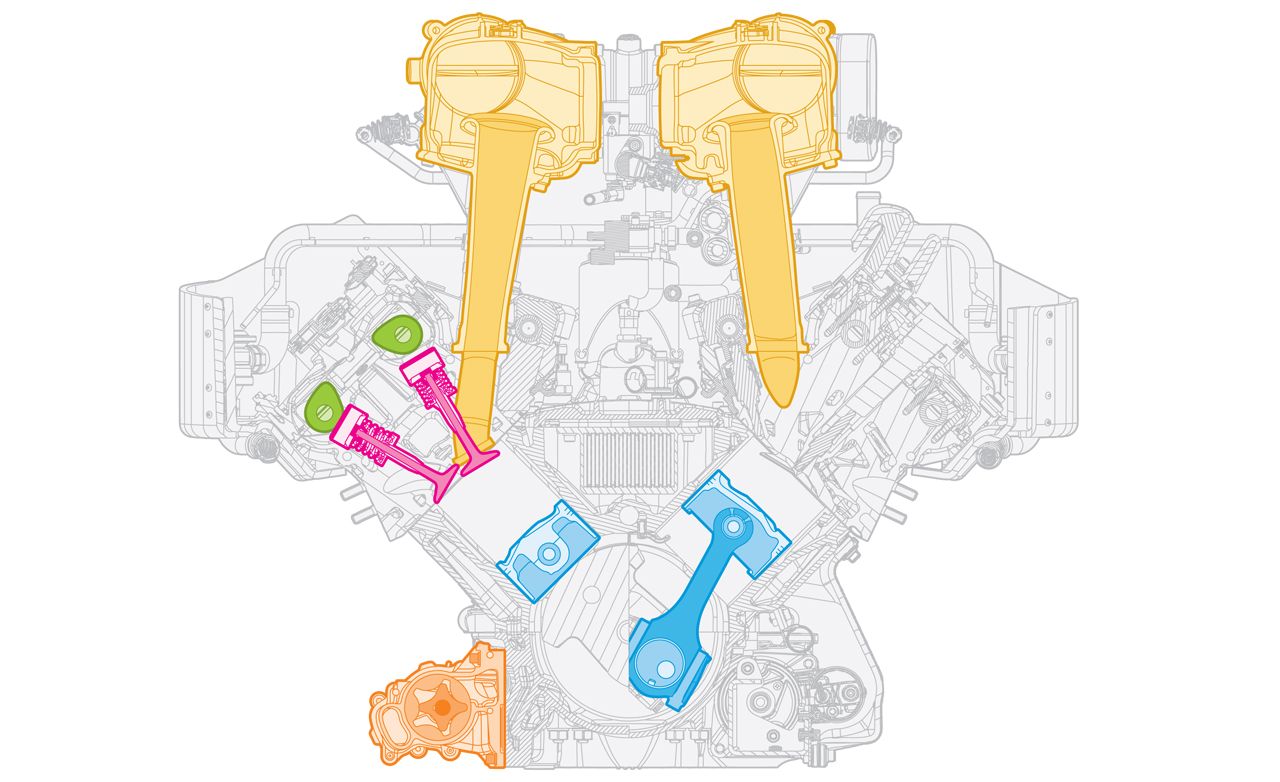

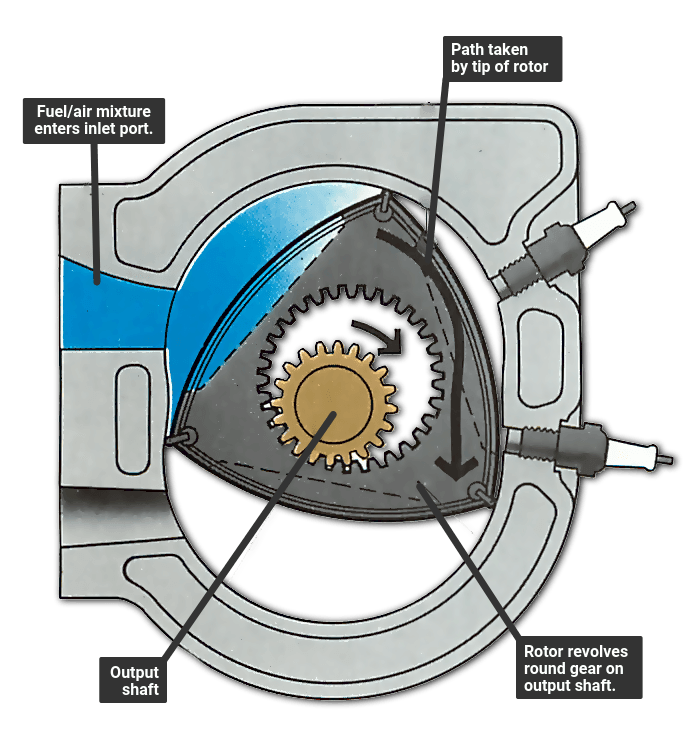

4. Wankel Engine (Rotary Engine)

The Wankel engine, also known as the rotary engine, uses a rotary motion instead of the traditional reciprocating motion. It features a triangular rotor within an epitrochoidal housing.

Figure: Wankel Engine Diagram

Key Features:

- Fuel Type: Gasoline

- Operation: Spark-ignition

- Efficiency: Compact and lightweight design

- Advantages: Smooth operation and high power-to-weight ratio

- Challenges: Lower fuel efficiency and higher emissions

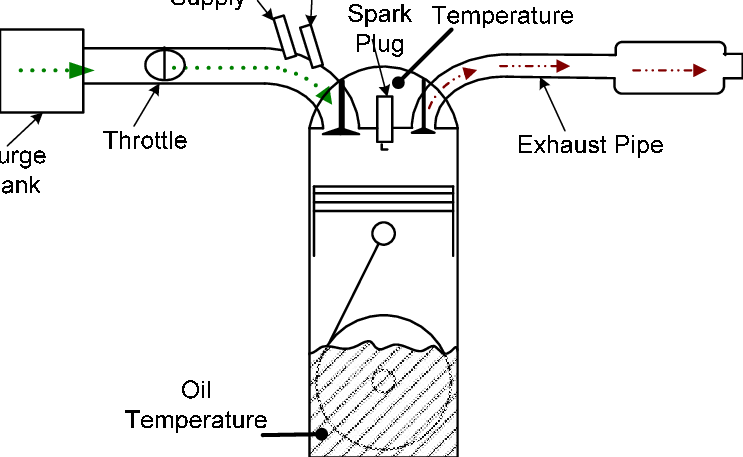

5. HCCI (Homogeneous Charge Compression Ignition) Engine

HCCI engines combine characteristics of both spark-ignition and compression-ignition engines. They use a homogeneous air-fuel mixture and compress it to the point of auto-ignition.

Figure: HCCI Engine Diagram

Key Features:

- Fuel Type: Gasoline or Diesel

- Operation: Auto-ignition

- Efficiency: High efficiency and low emissions

- Advantages: Better fuel economy and reduced emissions

- Challenges: Complex control and operating range limitations

Conclusion

Alternative engine cycles present a variety of options for improving vehicle efficiency, performance, and emissions. Each cycle has its unique advantages and challenges, making them suitable for different applications. Understanding these alternative cycles is crucial for advancing automotive technology and meeting future energy and environmental goals.