Anti-frosting Devices

Introduction:

An anti-frost device for refrigerators includes a heating mechanism capable of preventing any frost from being formed at the outlet portion of a cool air distribution duct, thus allowing cool air to effectively circulate in the cabinet of a refrigerator.

Working:

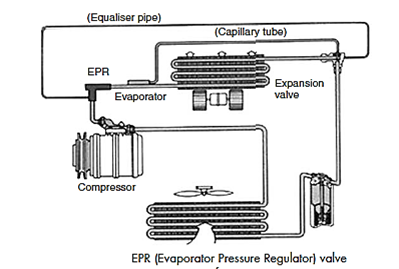

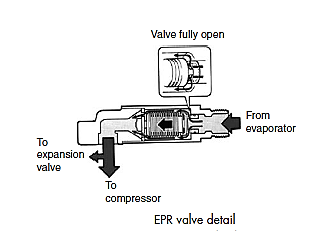

- The evaporator pressure regulator is mounted between the outlet of the evaporator and the compressor inlet (suction side).

- The valve regulates the pressure inside the evaporator to prevent icing.

- If the pressure drops below a certain threshold (196 kPa (28.4 psi)) then the valve closes to restrict the flow of refrigerant and increase the pressure inside the evaporator.

- This is to stop the evaporator temperature from reaching 0°C due to the relationship between temperature and pressure.

- When the cooling load is high the vapour pressure of the refrigerant in the evaporator is high.

- The valve fully opens and the refrigerant flows unobstructed to the compressor.

- The valve operation is based on a spring bellows which expands and contracts with changes in refrigerant pressure.

- This device virtually eliminates the need for the compressor to cycle on and off to regulate the temperature of the evaporator.

The only problem with this type of valve is the possibility of oil starvation due to the reduced flow of refrigerant.

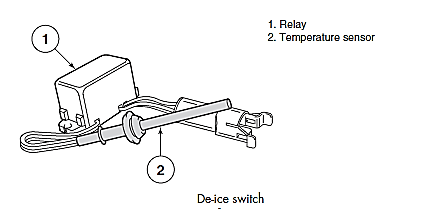

De-ice switch (TXV system)

- A de-ice switch is a temperature sensor and relay built as one unit. The temperature sensor is fitted to the evaporator’s fins and measures the temperature of the evaporator surface using an NTC type temperature sensitive resistor.

- This sensor sends the information to the relay in the form of a voltage drop and when approaching the freezing point of water (0°C) the current to the compressor clutch is interrupted to increase the pressure in the evaporator and avoid the surface water freezing.

- With a system threshold of 1°C at the surface, the relay will turn the compressor off. Once the surface increases to 2.5°C, the compressor, via the relay, will be switched on again.

Evaporator sensor

An evaporator sensor is used on a system which generally uses electronic control as opposed to electrical control. These systems use the temperature sensor to feed a voltage reading to a control module which is programmed to use the data and compare it to stored data in its memory.

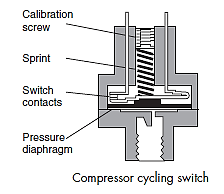

Compressor cycling switch (FOV system)

If the temperature in the evaporator approaches 0°C then icing will occur on the surface of the evaporator due to the water droplets which form. This will reduce the volume of air flowing through the evaporator and reduce the efficiency of the system. To prevent this a compressor cycling switch is fitted to the accumulator to deactivate the compressor clutch when a specific pressure is reached.