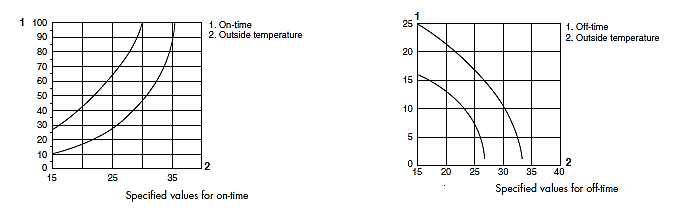

Cycle Time Testing

Introduction:

Measure the cycles using a stopwatch and make a note of the result. If the measured value lies outside the tolerance range then there is an error in the system. A serial tester can be used to monitor A/C compressor clutch activation.

Cycle time

The total cycle time is obtained by adding the on-time to the off-time.

The following conditions must be met before checking the switching cycle:

1. Connect the pressure gauges to the high and low pressure side of the air-conditioning system.

2. Start the engine and allow it to run for approximately 5 min at 1500 rev/min.

3. Set the air-conditioning to maximum cooling and air recirculation.

4. Set the blower to maximum power.

5. Adjust the interior temperature to approximately 22°C (if automatic temperature controlled) measured between the front head rests.

6. Measure the switching cycles using a stopwatch and make a note of the results.

7. Read off the pressure from the pressure gauges, make a note of the values and compare them with the required values in the diagrams.

A serial tester can be used to monitor A/C compressor clutch activation. An oscilloscope can also plot a trend graph showing cycle operation. An LED tester can be placed across the cycling switch and used to monitor switch operation (LED will flash).

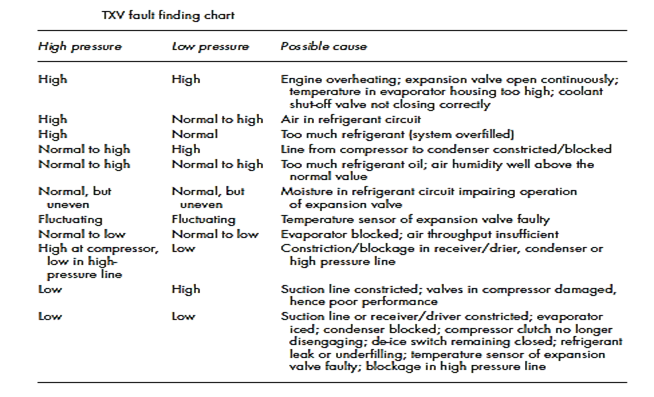

Expansion valve system

Table assists in diagnosing system faults. Use the pressure gauge readings to identify possible system faults.