Interior Heater

1. Fundamentals of Automotive Interior Heating

1.1 Heat Transfer Mechanisms

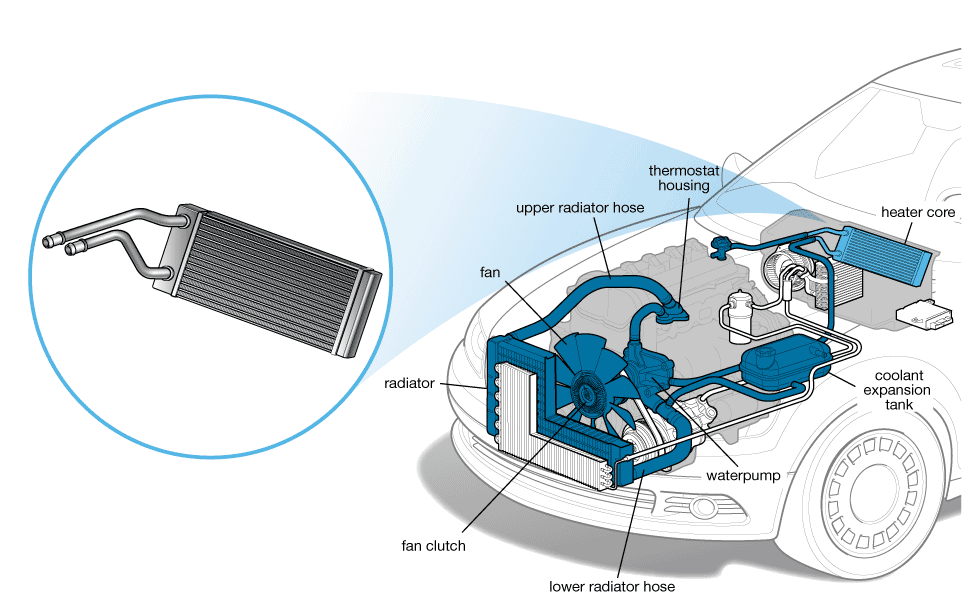

Automotive interior heaters primarily operate through heat transfer mechanisms that involve the engine's thermal energy. The core components include:

-

Engine Cooling System: The engine generates significant heat during combustion. This heat is absorbed by the engine coolant—a mixture of water and antifreeze—which circulates through the engine to manage thermal energy.

-

Heater Core: The heater core, akin to a small radiator within the HVAC (Heating, Ventilation, and Air Conditioning) module, serves as the primary heat exchanger. The hot coolant flows through the heater core, where it transfers heat to the surrounding air.

-

Blower Motor and Air Distribution: A blower motor forces air across the heater core, warming it before directing it into the cabin. The HVAC control system manages airflow, temperature, and distribution to ensure optimal comfort.

1.2 Heater Operation in Different Vehicle Types

-

Internal Combustion Engine (ICE) Vehicles: Traditional vehicles use engine heat for cabin heating. The system leverages the engine's cooling loop to provide warmth, offering a straightforward and reliable method of heating.

-

Hybrid and Electric Vehicles: These vehicles often use additional or alternative heating methods. Electric heaters or heat pumps are employed since these vehicles do not produce significant heat through engine operation alone.

2. Technical Design and Components

2.1 Heater Core Design

The design of the heater core is critical for efficient heat transfer. Key considerations include:

-

Material: Typically constructed from aluminum or copper, the choice of material impacts thermal conductivity and weight. Copper offers superior heat transfer but is heavier and more costly than aluminum.

-

Tube and Fin Configuration: The heater core consists of tubes through which coolant flows and fins that enhance heat dissipation. The design of these components affects the core’s efficiency. Fins increase the surface area, improving heat transfer to the airflow.

-

Flow Dynamics: Laminar flow within the tubes is preferred to minimize pressure drop and maximize heat exchange. The design of the flow path affects the heater core's effectiveness and efficiency.

2.2 Thermostatic and Control Systems

-

Thermostat: This component regulates engine temperature by controlling coolant flow to the heater core. It ensures the engine reaches its optimal operating temperature and provides consistent cabin heating.

-

Blower Motor: Controlled by a variable-speed system, the blower motor adjusts airflow through the heater core. Modern vehicles utilize electronically controlled motors to optimize air distribution and energy consumption.

-

HVAC Control Unit: Advanced HVAC systems use electronic controls to manage temperature settings, air distribution, and climate zones. These systems often incorporate sensors (temperature, humidity, and pressure) to deliver precise and adaptive climate control.

3. Advanced Technologies and Innovations

3.1 Electric Heating Systems

-

PTC Heaters: Positive Temperature Coefficient (PTC) heaters use ceramic elements that increase resistance as temperature rises, thereby generating more heat as needed. PTC heaters are common in electric vehicles and provide rapid, efficient cabin heating.

-

Heat Pumps: Heat pumps transfer heat from the outside air (even at low temperatures) into the cabin, offering energy-efficient heating. Heat pumps are increasingly used in hybrid and electric vehicles for both heating and cooling.

3.2 Integration with Vehicle Systems

-

Thermal Management Systems: Modern vehicles integrate heating systems with broader thermal management strategies to optimize fuel efficiency and emissions. This includes using waste heat recovery systems and advanced thermal insulation to reduce heat loss.

-

User Interfaces: Vehicles now feature sophisticated user interfaces that allow drivers to control the heating system through touchscreens or voice commands, integrating with other vehicle functions such as navigation and seat heating.

4. Maintenance and Troubleshooting

4.1 Common Issues

-

Coolant Leaks: Leaks in the heater core or cooling system can result in insufficient heating and potential engine overheating. Regular inspections and coolant level checks are essential.

-

Clogged Heater Core: Sediment and debris can clog the heater core, reducing efficiency. Flushing the cooling system periodically can help maintain proper function.

-

Blower Motor Failure: Symptoms include inconsistent airflow or a complete lack of air. Checking electrical connections and replacing faulty components can resolve these issues.

4.2 Diagnostic Tools

-

OBD-II Scanners: On-Board Diagnostics (OBD-II) scanners provide diagnostic trouble codes related to HVAC system components, aiding in accurate troubleshooting.

-

Thermal Cameras: Used to assess temperature distribution and identify hot or cold spots within the heater core and HVAC system.

5. Future Trends

5.1 Integration with Autonomous Driving Systems

As autonomous driving technology evolves, integration with climate control systems will become more sophisticated. Sensors and AI algorithms are expected to optimize heating based on external conditions, driving patterns, and passenger preferences.

5.2 Sustainability and Efficiency

Future developments will focus on enhancing energy efficiency and reducing the environmental impact of heating systems. Advances in materials, such as lightweight and more effective heat exchangers, and innovations in electric heating technologies will be crucial.