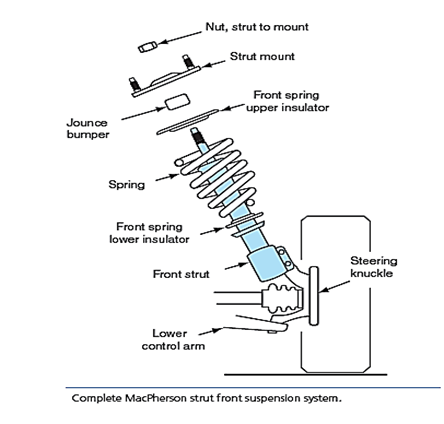

Macpherson Strut Front Suspension System Design

Introduction:

Rear-wheel-drive cars usually have short-and-long arm or torsion bar front suspension systems. Since space and weight are important factors on today’s smaller, more efficient front-wheel-drive cars, the lighter, more compact MacPherson strut front suspension is used on most of these cars.

MacPherson strut front suspension system

- The front wheel bearing assembly is bolted to the outer end of the steering knuckle, and the brake rotor and wheel rim are retained on the studs in the wheel bearing assembly.

- This front wheel bearing assembly is a complete, nonserviceable, sealed unit.

- The front drive shaft is splined into the center of the wheel bearing hub.

- Thus, drive axle torque is applied to the front wheel.

- A tie-rod end connects the steering linkage from the steering gear to the steering knuckle.

- The top end of the steering knuckle is bolted to the lower end of the strut.

The purpose of the main components in a MacPherson strut front suspension system may be summarized as follows:

1. Lower control arm—controls lateral (side-to-side) movement of each front wheel.

2. Stabilizer bar—reduces body roll when a front wheel strikes a road irregularity.

3. Coil springs—allows proper setting of suspension ride heights and control suspension travel during driving maneuvers.

4. Shock absorber struts—provides necessary suspension damping and limit downward wheel movement with an internal rebound stop and upward wheel movement with an external jounce bouncer.

5. Strut upper mount—insulates the strut and spring from the body and provides a bearing pivot for the strut-and-spring assembly.

6. Ball joint—connects the outer end of the lower control arm to the steering knuckle and acts as a pivot for the strut, spring, and knuckle assembly.