Mean Effective Pressure And Torque

Introduction

In internal combustion engines (ICEs), performance metrics such as Mean Effective Pressure (MEP) and torque are fundamental to understanding engine efficiency and power output. These parameters are critical for engineers to design, evaluate, and optimize engine performance. This comprehensive study delves into the technical aspects of MEP and torque, including their definitions, calculation methods, implications, and their role in engine design and performance analysis.

Mean Effective Pressure (MEP)

Definition and Importance

Mean Effective Pressure (MEP) is a crucial indicator of engine performance, representing the average pressure exerted on the piston during the power stroke. It provides a measure of the engine's efficiency and power output relative to its displacement. MEP is essential for comparing engines of different sizes and configurations, as it normalizes the pressure across the engine's cycle.

Calculation Methods

MEP can be categorized into different types based on its calculation method:

-

Indicated Mean Effective Pressure (IMEP):

- Definition: IMEP is the average pressure calculated from the work done by the engine's combustion process, measured from the indicated work (i.e., work before losses).

- Formula:

Where is the work done per cycle (indicated work), and is the engine displacement. - Measurement: IMEP is often determined using a pressure sensor or indicator diagram, which captures cylinder pressure throughout the engine cycle.

-

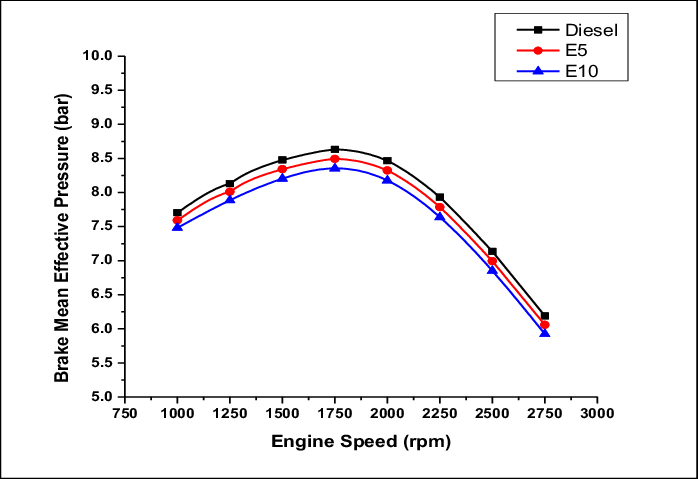

Brake Mean Effective Pressure (BMEP):

- Definition: BMEP is the average pressure that represents the work delivered to the crankshaft, measured after losses due to friction and other mechanical inefficiencies.

- Formula:

Where is the brake torque and is the engine displacement. - Measurement: BMEP is derived from brake torque measurements, which are obtained using a dynamometer.

-

Effective Mean Pressure (EMEP):

- Definition: EMEP is an average pressure value that includes various losses such as friction and heat dissipation.

- Usage: Although less common, EMEP can provide a more comprehensive view of engine performance when considering various operational conditions.

Significance in Engine Design

- Engine Efficiency: MEP is a direct indicator of engine efficiency, as it reflects how effectively the engine converts fuel into work.

- Comparative Analysis: MEP allows for fair comparisons between engines of different sizes and configurations, as it normalizes the performance relative to engine displacement.

- Optimization: Engineers use MEP to optimize engine design parameters such as cylinder pressure, combustion efficiency, and overall power output.

Torque

Definition and Types

Torque is a measure of the rotational force produced by the engine's crankshaft. It is a critical parameter for assessing engine performance, as it directly correlates with the engine’s ability to perform work. Torque can be measured at various stages:

-

Brake Torque (T):

- Definition: Brake torque is the engine’s output torque measured at the crankshaft after accounting for losses due to friction and other parasitic factors.

- Measurement: Typically measured using a dynamometer, which applies a load to the engine and measures the resulting torque.

-

Indicated Torque:

- Definition: Indicated torque refers to the torque calculated from the indicated work done by the engine before losses are considered.

- Usage: This metric helps in evaluating the engine’s potential output under ideal conditions.

Calculation of Torque

Torque is related to the engine’s power output and rotational speed. The formula linking these variables is:

Where is the torque, is the power output, and is the angular velocity (in radians per second).

Significance in Engine Performance

- Power Output: Torque is a key component of engine power, as power () is the product of torque and engine speed ():

- Vehicle Dynamics: Torque affects vehicle acceleration and towing capability. Higher torque values contribute to better performance in terms of acceleration and load handling.

- Engine Tuning: Engineers use torque curves to optimize engine tuning, improving performance characteristics such as throttle response and fuel efficiency.

Relationship Between MEP and Torque

The relationship between Mean Effective Pressure (MEP) and torque is integral to understanding engine performance. Both MEP and torque provide insights into different aspects of engine efficiency:

-

Theoretical Relationship:

- MEP is related to the work done by the engine per cycle and is directly proportional to torque when engine displacement and speed are constant. The fundamental relationship is:

- This equation indicates that BMEP can be used to calculate brake torque if engine displacement and speed are known.

- MEP is related to the work done by the engine per cycle and is directly proportional to torque when engine displacement and speed are constant. The fundamental relationship is:

-

Practical Implications:

- High MEP values often correlate with higher torque output, indicating an efficient combustion process and effective utilization of engine displacement.

- Analyzing MEP and torque together provides a comprehensive view of engine performance, highlighting areas for improvement and optimization.

Measurement Techniques

-

Dynamometer Testing:

- Purpose: Measures brake torque and power output.

- Procedure: The engine is tested under controlled conditions, and torque is measured using a dynamometer that applies load and measures rotational force.

-

Pressure Sensors and Indicator Diagrams:

- Purpose: Measures cylinder pressure to determine IMEP.

- Procedure: Pressure sensors capture data throughout the engine cycle, which is analyzed to determine the average pressure.

-

Data Acquisition Systems:

- Purpose: Collects and analyzes engine performance data.

- Procedure: Modern systems use advanced sensors and data loggers to measure parameters such as torque, pressure, and engine speed.

Mean Effective Pressure (MEP) and torque are fundamental parameters in assessing internal combustion engine performance. MEP provides insight into engine efficiency and power output relative to displacement, while torque represents the rotational force produced by the engine. Understanding these metrics allows engineers to design, evaluate, and optimize engine performance, ensuring that engines meet performance and efficiency standards. Through accurate measurement and analysis, automotive engineers can enhance engine design, improve fuel efficiency, and achieve better overall performance.