Oil Pumps

Introduction

Oil pumps are crucial components in automobile engines, ensuring that the engine's moving parts are lubricated and functioning smoothly. This chapter explores the various types of oil pumps, their operational principles, and their significance in maintaining engine performance and longevity.

Function of Oil Pumps

The primary function of an oil pump is to circulate engine oil throughout the engine. This circulation lubricates the engine's components, reduces friction, and helps in cooling the engine. Proper lubrication is essential for:

- Reducing Wear and Tear: By providing a constant supply of oil to moving parts, oil pumps help minimize friction and wear.

- Cooling: Engine oil absorbs heat from the engine components, helping to maintain optimal operating temperatures.

- Cleaning: Oil pumps help in removing contaminants from the engine by circulating the oil through the oil filter.

Types of Oil Pumps

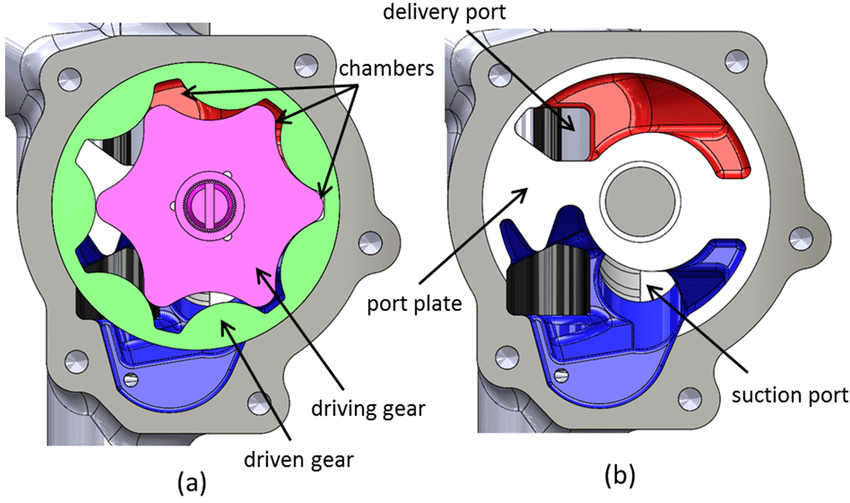

1. Gear Pumps

Gear pumps are the most common type of oil pump used in automobile engines. They consist of two interlocking gears: a driving gear and a driven gear. As the gears rotate, they trap oil between the gears and the pump housing, pushing it through the engine.

Advantages:

- Simple design

- Reliable performance

- Cost-effective

Disadvantages:

- Limited flow rate compared to other types

- Can be noisy

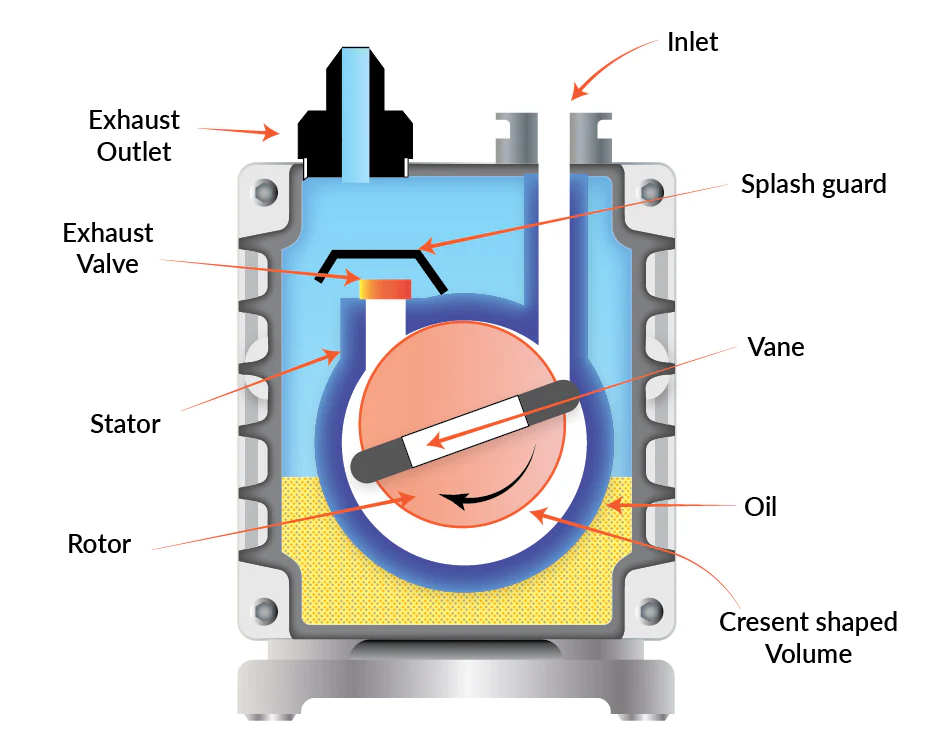

2. Rotor Pumps

Rotor pumps, also known as rotary vane pumps, use a rotating rotor and sliding vanes to pump oil. The rotor rotates inside a cavity, creating a chamber that moves oil from the inlet to the outlet.

Advantages:

- High flow rate

- Smooth and quiet operation

Disadvantages:

- More complex design

- Higher cost

3. Gerotor Pumps

Gerotor pumps use a rotor inside an outer gear, with an eccentric motion creating a pumping action. They are known for their smooth and efficient operation.

Advantages:

- Compact design

- Efficient and reliable

Disadvantages:

- Higher manufacturing complexity

Oil Pump Operation

The oil pump is driven by the engine crankshaft or camshaft. As the engine operates, the pump draws oil from the oil pan and forces it through the engine's oil passages. The oil then lubricates various engine components, including the pistons, crankshaft, and camshaft.

Lubrication Process:

- Oil Intake: Oil is drawn from the oil pan into the pump.

- Pressure Generation: The pump pressurizes the oil and directs it through the oil filter.

- Distribution: Filtered oil is distributed through the engine to lubricate the moving parts.

- Return: The oil eventually returns to the oil pan, where the cycle begins again.

Importance of Regular Maintenance

Maintaining the oil pump is vital for engine health. Regular oil changes and inspections ensure that the oil pump operates efficiently. Neglecting maintenance can lead to:

- Engine Wear: Insufficient lubrication can cause increased wear and tear on engine components.

- Overheating: Lack of proper oil circulation can lead to overheating and potential engine damage.

- Engine Failure: In extreme cases, a failing oil pump can lead to complete engine failure.

Conclusion

Oil pumps are integral to the smooth and efficient operation of automobile engines. Understanding their types, functions, and maintenance needs is essential for ensuring the longevity and performance of an engine. Regular inspections and timely maintenance of oil pumps can prevent costly repairs and keep the engine running smoothly.