Power And Mechanical Efficiency

Definition:

Power in the context of automobiles refers to the rate at which work is done by the engine. It is a measure of how quickly the engine can do work, and it directly affects the vehicle's performance, including acceleration and top speed.

Units and Measurement:

Power is measured in units such as horsepower (hp) and kilowatts (kW).

- 1 horsepower is equivalent to approximately 746 watts.

- 1 kilowatt is equivalent to 1,000 watts.

Engine Power Output:

The power output of an engine is usually specified in the engine’s technical documentation. It is determined by factors such as engine displacement, the number of cylinders, fuel type, and engine design.

Performance Parameters:

- Torque: It’s the rotational force generated by the engine. Higher torque means better acceleration.

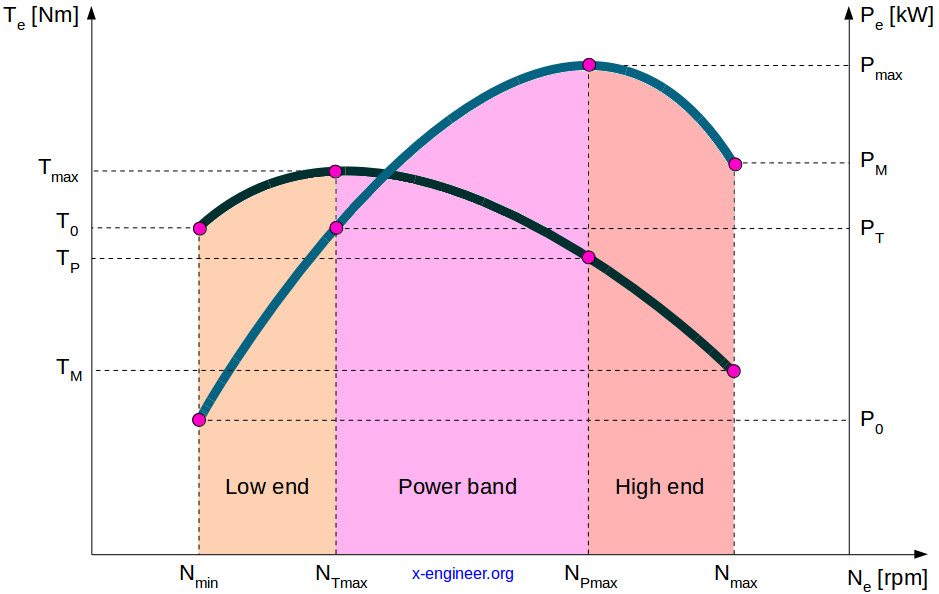

- RPM (Revolutions Per Minute): Power output is also a function of RPM. Power typically increases with RPM, but there is a peak power output at a specific RPM range.

Power Curve:

The power curve represents how engine power varies with RPM. An engine with a flat power curve delivers consistent power across a wide RPM range, which improves driveability and performance.

Mechanical Efficiency

Definition:

Mechanical efficiency refers to how well an engine converts the energy from fuel into useful mechanical work. It’s a measure of how effectively the engine uses the energy produced by combustion to drive the vehicle.

Formula:

- Brake Power (BP): The actual power available at the engine’s output shaft, measured using a dynamometer.

- Indicated Power (IP): The theoretical power produced by the combustion process within the engine's cylinders.

Factors Affecting Mechanical Efficiency:

- Friction Losses: Mechanical components such as pistons, crankshafts, and camshafts create friction, which consumes some of the engine’s power.

- Heat Losses: Some energy is lost as heat through the engine’s cooling system, exhaust system, and other components.

- Engine Design: Engine designs, such as the type of lubrication system, the precision of engine components, and the engine’s thermal efficiency, influence mechanical efficiency.

Improving Mechanical Efficiency:

- Advanced Materials: Using materials with better thermal and mechanical properties reduces friction and wear.

- Precision Engineering: Better machining and tighter tolerances improve the fit of engine components, reducing friction losses.

- Lubrication: Advanced lubricants reduce friction and wear, improving overall efficiency.

- Engine Tuning: Optimizing the engine’s tuning, such as fuel injection timing and air-fuel ratio, can enhance efficiency.

Practical Implications

Fuel Economy:

Mechanical efficiency has a direct impact on fuel economy. Engines with higher mechanical efficiency require less fuel to produce the same amount of power, leading to better fuel economy.

Performance:

Higher power output generally translates to better vehicle performance. However, achieving a balance between power and mechanical efficiency is crucial to avoid excessive fuel consumption and wear.

Emissions:

Improved mechanical efficiency often leads to reduced emissions. Efficient engines burn fuel more completely, resulting in lower levels of pollutants in the exhaust gases.

Real-World Applications

Engine Testing:

Automobile engineers use dynamometers to measure both brake power and indicated power. This data helps in evaluating the engine’s performance and efficiency.

Vehicle Development:

Engineers use simulations and real-world testing to optimize engine designs for both power output and mechanical efficiency. This includes developing hybrid and electric powertrains, which often focus on maximizing overall efficiency.

Maintenance:

Regular maintenance of the engine, including oil changes and component checks, helps maintain mechanical efficiency over the life of the vehicle.