Rear Suspension Systems- Introduction

Introduction:

The rear suspension system plays a very important part in ride quality and in the control of suspension and differential noise, vibration, and shock. Although the front wheels actually steer the vehicle, the rear suspension is also vital to steering control. The rear suspension must also provide adequate tire life and maintain tire traction on the road surface. Rear suspension systems described in this chapter include live-axle, semi-independent, and independent.

Vibration Theory

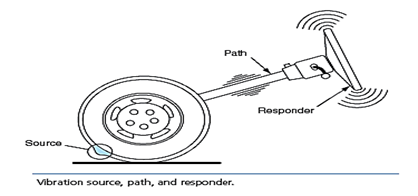

Vibrations have these three elements:

1. Source—the cause of the vibration

2. Path—where the vibration travels through the vehicle

3. Responder—the component where the vibration is felt.

For example, if the vehicle has an unbalanced tire, this is the vibration source. The vibration path is the steering and suspension system through which the vibration travels. The responder is the steering wheel because this component is where the customer feels the vibration. When diagnosing vibration problems, locate and correct the source of the vibration. In the previous example of the unbalanced tire, installing a rigid brace from the steering column to the instrument panel and chassis may reduce the vibration experienced by the customer, but this does not solve the problem. To eliminate the problem, also diagnose the unbalanced tire condition and then balance the tire-and-wheel assembly.

Vibration cycles

Vehicle vibrations may be tested with an electronic vibration analyzer (EVA).

- The EVA has a vibration sensor that is mounted on the suspected vibration source.

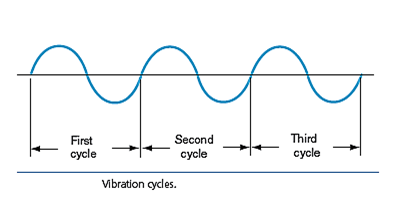

- The EVA senses and records vibration cycles. A vibration cycle begins and ends at the same point and is continually repeated.

- Cycles per second are measured in Hertz (Hz), and the Hz may be multiplied by 60 to obtain the cycles per minute.

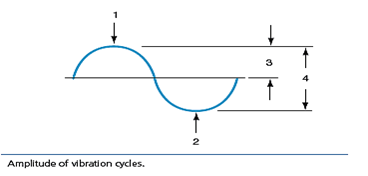

- The amplitude of a vibration is the maximum value of the varying vibration. Point 1 represents the maximum amplitude, 2 is the minimum amplitude, 3 is the zero-to-peak amplitude, and 4 indicate the peak-to-peak amplitude.

- The vibration amplitude may vary with the rotating speed of a component. For example, if a tire-and-wheel assembly is unbalanced, the amplitude of the resulting vibrations increases with wheel speed.

- All objects have natural vibration frequencies. The natural frequency of a front suspension system is 10 to 15 Hz. The suspension system design determines the natural frequency.

- The natural frequency of the suspension system is the same at all vehicle speeds. The vibration frequency caused by unbalanced tire-and-wheel assembly increases with wheel speed.

- When the vibration frequency caused by the wheel balance problem intersects with the natural frequency of the suspension system, the suspension system begins to vibrate.

- This intersection point is called the resonance.