←

Automobile Engineering

Rolling Resistance

↵

Introduction:

Rolling resistance or rolling friction or rolling drag, is the force resisting the motion when a body (such as a ball, tire, or wheel) rolls on a surface.

Basics of rolling resistance:

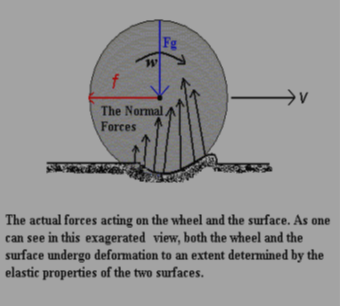

- due to the deformation of the tire at the tire/road interface

- tire deformation consumes energy

- an unequal force is needed during compression and elastic recovery

- Therefore: the normal pressure distribution over the tire/road contact patch is not uniform.

- the normal force is higher in the leading half of the contact patch than in the trailing half

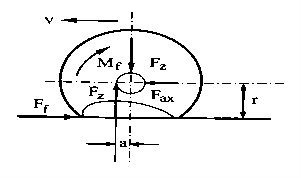

- the normal force produces a moment about the axis of rotation of the tire

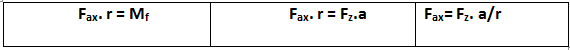

- rolling resistance moment: Mf= Fz.a

- The driving force fax, applied to the wheel produces a moment to balance the rolling resistance moment.

- In the actual case of a rolling wheel, both the wheel and the surface will undergo deformations due to their particular elastic characteristics.

- At the contact points, the wheel flattens out while a small trench is formed in the surface

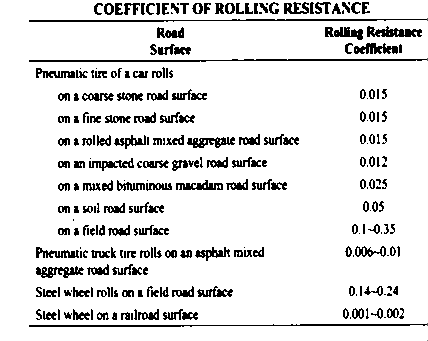

- Experiments show: rolling resistance is:

- proportional to the tire deformation

- Inversely proportional to the radius of the loaded tire.

ACCORDING TO THE US STANDARD:

- -IF v<50 km/h : f = 0,0165

- -IF v>50 km/h : f = 0,0165 [1 00,1.(v –50)]