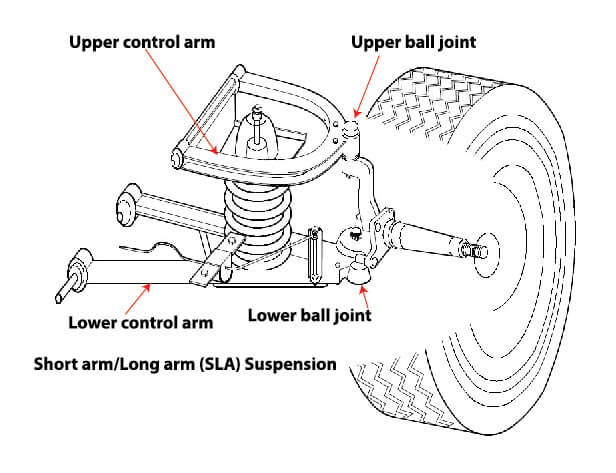

Short-and-long Arm Front Suspension Systems

Short-and-long arm (SLA) suspension systems, also known as double wishbone suspension systems, are widely used in vehicles for their superior handling characteristics and ability to maintain optimal tire contact with the road. Here’s an overview of SLA front suspension systems:

1. Components of SLA Suspension:

- Upper Control Arm (Short Arm): A shorter arm connected to the upper part of the wheel hub and chassis. This arm controls the vertical motion of the suspension.

- Lower Control Arm (Long Arm): A longer arm connected to the lower part of the wheel hub and chassis. This arm also controls the vertical motion and supports the weight of the vehicle.

- Steering Knuckle: Connects the upper and lower control arms to the wheel assembly, allowing the wheel to pivot for steering.

- Shock Absorber and Coil Spring: Usually mounted between the lower control arm and the chassis, providing damping and support for the vehicle’s weight.

- Ball Joints: Allow for the rotation and movement of the control arms relative to the wheel assembly.

- Stabilizer Bar (Anti-Roll Bar): Connects the left and right sides of the suspension to reduce body roll during cornering.

2. Functionality:

- Independent Suspension: Each wheel on the SLA system operates independently, meaning bumps or road irregularities affecting one wheel do not necessarily affect the other.

- Camber Control: The design of the upper and lower control arms allows for better control over the camber angle of the wheels. The camber angle changes less drastically with suspension movement, which helps maintain better tire contact with the road.

- Handling and Stability: SLA suspension provides precise handling, better cornering stability, and reduced body roll compared to simpler suspension systems.

3. Advantages:

- Improved Handling: The geometry of the short-and-long arm system allows for better control over the wheel’s camber, toe, and caster angles, which improves handling.

- Ride Comfort: The independent nature of the system provides a smoother ride, especially on uneven surfaces.

- Customization: The design allows for easy adjustment of various suspension parameters, making it popular in performance and racing vehicles.

4. Disadvantages:

- Complexity: SLA suspension systems are more complex and require more components than simpler suspension systems like MacPherson struts.

- Space Requirements: The system takes up more space in the vehicle’s chassis, which can be a limitation in smaller vehicles.

- Cost: Due to the complexity and number of parts, SLA suspensions are generally more expensive to manufacture and maintain.

5. Applications:

- High-Performance Vehicles: Often found in sports cars and high-end vehicles where precise handling is critical.

- Luxury Vehicles: Used in vehicles where ride comfort and smooth handling are prioritised.

6. Operation Mechanism:

- Camber Gain: As the wheel moves up and down, the camber angle changes in a way that maintains optimal tire contact with the road, especially during cornering.

- Anti-Dive and Anti-Squat: The design can include anti-dive and anti-squat geometry, which controls the vehicle’s pitch during braking and acceleration.

Visualizing SLA Suspension:

To visualise an SLA suspension system:

-

Upper Control Arm: Typically shorter and angled upward, connecting the top of the wheel hub to the chassis.

-

Lower Control Arm: Longer, running almost parallel to the ground, connecting the lower part of the wheel hub to the chassis.

-

Shock Absorber: Positioned vertically between the lower control arm and the chassis, sometimes accompanied by a coil spring.

These components work together to maintain optimal wheel alignment and vehicle stability.