System Operation

Introduction:

The coolant is a mixture of water, antifreeze and inhibitors. The antifreeze is usually ethylene glycol, which needs inhibitors to prevent corrosion and foaming. These inhibitors have a lifespan of about two years, which means that the coolant should be changed at these intervals. Selection of the correct coolant mixture must be made to meet the manufacturer’s specifi cations. Aluminium alloy engines are more prone to corrosion than cast-iron engines.

Forms of the heat transfer:

All three forms of heat transfer are used in the cooling system:

● Convection occurs in the water jacket, creating flows of internal coolant from the cylinder block to the cylinder head

● Conduction occurs through the cylinder and combustion chamber surfaces as heat passes to the coolant

● Radiation of heat occurs from the radiator and cooling fi ns when heat is dissipated to the atmosphere

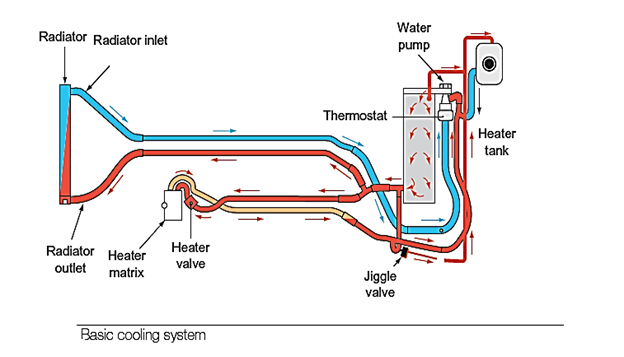

Basic cooling system:

- The coolant reheats in the engine, the thermostat opens, and the cycle of hot coolant flow to the radiator and cool coolant returning to the engine repeats itself.

- Although this system provides a reasonably effective method of engine temperature control, it produces a fluctuating temperature.

- However, a steady temperature is required for very clean and efficient combustion.

- Many vehicles, particularly those fitted with air conditioning, have two-speed fan circuits.

- These have a control circuit to switch the motor (or motors) to half speed at 95°C, and full speed at 100°C. This arrangement can be also be operated by the engine management system.

- Cooling system hoses are manufactured from fabric-reinforced rubber, and are moulded to suit the vehicle application.

- Connectors are cast, or formed, with a raised lip on the pipes leading into, and out of, other components.

- The hoses are held with round clips that can be drawn tight to give a watertight seal (e.g. jubilee clips).