The Expansion Valve/fixed Orifice Valve

Introduction:

To control the amount of refrigerant volume flowing through the evaporator a metering device must be used. TXV (thermostatic expansion valve) meters the refrigerant to the evaporator using a thermal sensing element to monitor the superheat. Dual air-conditioning systems may use both a TXV and an FOV within the system.

FUNCTION OF THE METERING DEVICE: The function of the metering device is as follows:

- To separate the high pressure and low pressure side of the system

- To meter the volume of refrigerant and hence the cooling capacity of the evaporator

- To ensure that there is superheated refrigerant exiting the evaporator

Currently there are two main categories of metering device used, a Thermostatic Expansion Valve (TXV or TEV) and a Fixed Orifice Valve (FOV).The pressure drop across the evaporator is used to determine which type of valve is the most appropriate. Simple air-conditioning systems will generally use only one of these metering devices. Dual air-conditioning systems may use both a TXV and an FOV within the system.

Thermostatic expansion valve

There are also some variations in the design of a TXV.

● Internally equalized thermostatic expansion valve

● Externally equalized expansion valve

● Box or H-valve type

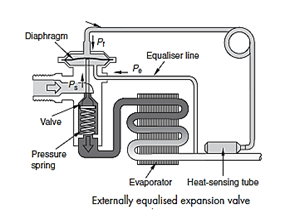

Operation of externally equalised expansion valve

There are three pressures acting on the diaphragm of a TXV valve:

1. Refrigerant within or exiting the evaporator applies pressure under the diaphragm (Pe).

2. Spring pressure (called superheat spring) applying pressure against a pintle valve (ball and seat).This pressure is applied under the diaphragm (Ps).

3. Pressure from the expansion of the liquid within the heat sensing bulb via the capillary tube (Pf) which is above the diaphragm.

- This high temperature will be transferred to the heat sensing tube (remote bulb) which contains an inert liquid (different to the refrigerant) which expands within the bulb increasing in pressure due to its fixed volume.

- The increase in pressure is transferred via the capillary tube to the top of the diaphragm enabling the diaphragm to overcome the combined pressure of the superheat spring (Ps) and the refrigerant exiting (Pe).

- The valve opens further and allows an increase in volume of refrigerant to flow through the evaporator to cope with the increase in load. This will lower the temperature of the refrigerant exiting the evaporator.

- This reduction in temperature will be transferred to the heat sensing tube and cause the liquid inside to contract.

Operation of internally equalised expansion valve

- The operation of the internally equalised expansion valve is almost the same as the externally equalised expansion valve. The difference is the loss of the benefit of sensing the pressure of the refrigerant as it leaves the outlet of the evaporator.

- The pressure is sensed on the inlet of the evaporator or just before, using an internal drilling inside the housing of the TXV where refrigerant entering can apply pressure on the underside of the diaphragm.

- This means that the pressure drop across the evaporator is unknown with this type of valve.

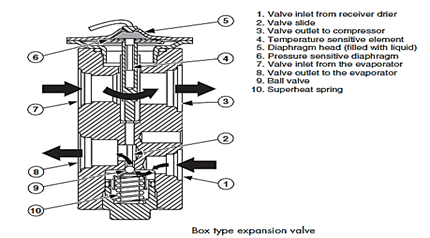

Box or H-valve type

- The box type expansion valve includes the pressure sensing and temperature sensing functions of the externally equalised TXV but has no external tubes (capillary or pressure sensing).

- This is achieved by using two passages – one entering the evaporator and one exiting the evaporator.