Tire Ply And Belt Design

Introduction:

Today there is a cultivated rubber tree for every two human beings on earth and three million people are employed collecting the rubber from the trees in various countries. The tire plies and belts must be level across the tread area. If the plies and/or belts are not level across the tread area, the tire is cone shaped. This condition is referred to as tire conicity.

TYPES OF TIRE CONSTRUCTION:

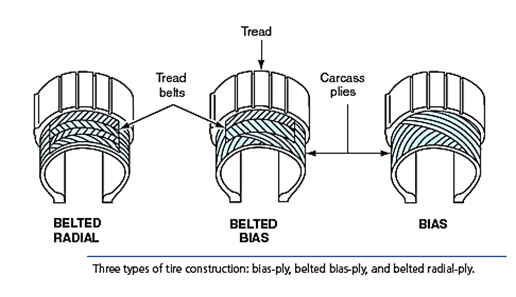

- The most commonly used tire designs are bias, belted bias, and belted radial.

- In bias-ply or belted bias-ply tires, the cords crisscross each other. These cords are usually at an angle of 25° to 45° to the tire centerline.

- The belt-ply cord angle is usually 5° less than the cord angle in the tire casing.

- Two plies and two belts are most commonly used, but four plies and four belts may be used in some tires.

- Compared to a bias-ply tire, a belted bias-ply tire has greater tread rigidity. The belts reduce tread motion during road contact. This action provides extended tread life compared to a bias-ply tire.

- In radial-ply tires, the ply cords are arranged radially at a right angle to the tire centerline. Steel belts are most commonly used in radial tires, but other belt materials such as fiberglass, nylon, and rayon have also been used.

- The steel or fiberglass cords in the belts are crisscrossed at an angle of 10° to 30° in relation to the tire centerline. Many radial tires have two plies and two belts.

- Radial tires provide less rolling resistance, better steering characteristics, and longer tread life than bias-ply tires.

- Regardless of the type of tire construction, the tire must be uniform in diameter and width. Radial run out refers to variations in tire diameter.

- A tire with excessive radial runout causes a tire thumping problem as the car is driven. When a tire has excessive variations in width, this condition is called lateral runout. A tire with excessive lateral run out causes the chassis to “waddle” when the car is driven.

The tire plies and belts must be level across the tread area. If the plies and/or belts are not level across the tread area, the tire is cone shaped. This condition is referred to as tire conicity. When a front tire has conicity, the steering may pull to one side as the car is driven straight ahead. A rear tire with conicity will not affect the steering as much as a front tire with conicity.