←

Automobile Engineering

Universal Joint

Introduction:

A universal joint takes care of rising and falling motion of the rear end of the propeller shaft which is connected to differential.

Concept of Universal joint:

- Universal joint is used to connect two shafts at an angle for transmitting torque.

- In the transmission shaft of an automobile, two universal joints are used – one between main transmission shaft and propeller shaft and another between other end of propeller shaft and the differential.

- Therefore, the universal joints make the joints flexible so that power can be transmitted at an angle.

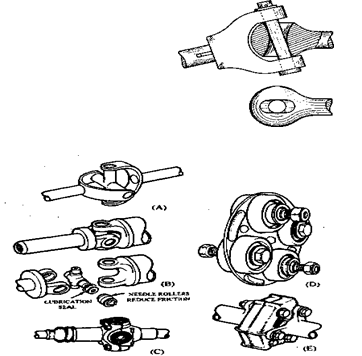

Types of the universal joints:

Three types of universal joints are commonly used. These are listed below:

(a) Cross or spider joint (variable velocity joint).

(b) Ball and trunnion joint (variable velocity joint).

(c) Constant velocity joints.

Cross Type Universal Joint (B and C)

- It consists of two Y-shaped yokes and a cross piece (spider). One yoke is connected to driving shaft and other is connected to driven shaft. The cross-piece has four-arms which are known as trunnions and are attached to the ends of yokes. Four needle bearings are provided – one for each arm of cross-piece. These bearings allow the yoke to swing around the trunnion when driving and driven shaft remove together at an angle.

Ball and Trunnion Joint:

- This type of joint consists of a ball type head which is fastened to one end of the propeller shaft. A pin is also pressed through this end of shaft. Two steel balls are fitted at the end of this pin. The joint facilitates rotary motion through ball and pin. The balls can also move axially.

- Ball and trunnion joint is also a variable velocity joint.

Constant Velocity Universal Joint

- This type of joint permits movement of both driving and driven shafts at constant velocity. Because, two joints in this case operate at same angles. These joints are generally used when the automobile in a front wheel (axle) drive. Because speed variation between driving and driven shaft will introduce difficulty in steering and excessive tire wear.