←

Automobile Engineering

Wheel Rims

Introduction:

Many wheel rims are manufactured from stamped or pressed steel discs that are riveted or welded together to form the circular rim. Currently, less than 50 percent of the wheel rims installed by the original equipment manufacturers (OEMs) are stamped steel type.

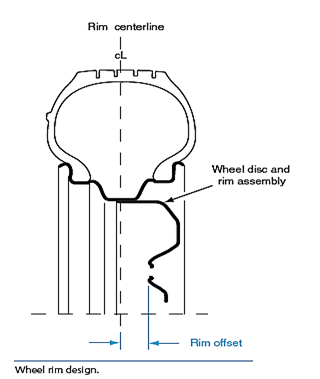

Wheel rim design:

- The rim offset is the distance between the rim centerline and the mounting face of the disc.

- If a rim is designed with positive offset, the rim centerline is outboard of the mounting face.

- The rim with negative offset has the centerline inboard of the mounting face.

- The rim offset affects front suspension loading and operation.

- A large hole in the center of the rim fits over a flange on the mounting surface.

- The rim has a small hole for the valve stem.

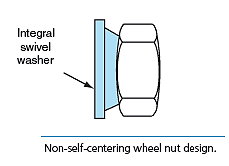

- The wheel stud mounting holes in the rim are tapered to match the taper on the wheel nuts. Some late model Ford trucks have non-self-centering wheel nuts.

- On these nuts, a swivel washer is attached to the inner side of each nut. When the wheel and nuts are installed, the flat side of the swivel nut fits against the wheel rim.

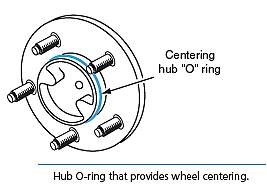

- The wheels are hub-centered, and an O-ring mounted on the hub provides improved wheel centering. If this O-ring is missing or damaged, the wheel may not be properly centered, and this condition results in wheel vibrations.

- The O-ring also provides a seal to prevent corrosion.

- The width of the wheel is measured between the rim flanges. Rim diameter is determined by measuring across the wheel from the top to the bottom.

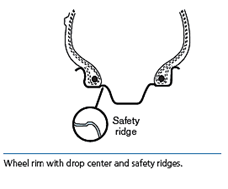

- A drop center in the rim makes tire changing easier.

- Rims have safety ridges behind the tire bead locations, which help prevent the beads from moving into the drop center area if the tire blows out. If the tire blows out and a bead enters the drop center area, the tire may come off the wheel.