Derivation Of An Expression For Eddy Current Loss In A Thin Plate

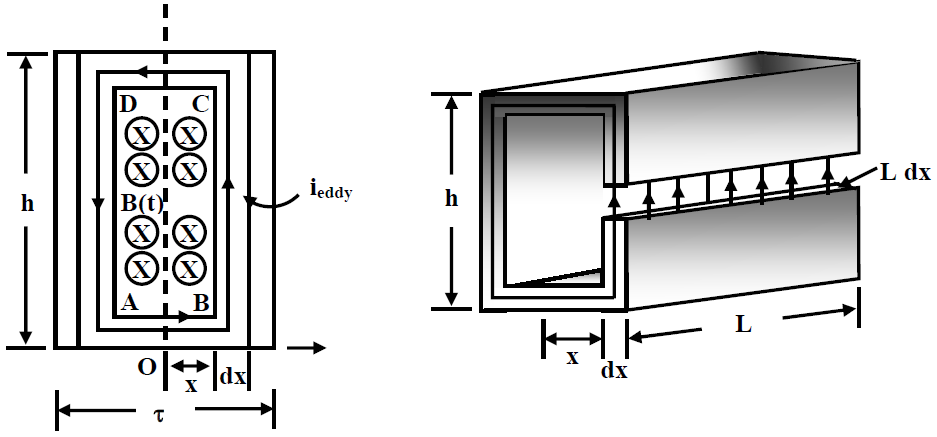

Derivation of an expression for eddy current loss in a thin plate: From physical consideration we have seen that thin plates each of thickness τ, are to be used to reduce eddy loss. With this in mind we shall try to derive an approximate expression for eddy loss in the following section for a thin plate and try to identify the factors on which it will depend. Section of a thin plate τ << L and h is shown in the plane of the screen in Figure (A).

fig(A).Elemental eddy current path fig(B)Section of the elemental eddy current path.

Eddy current loss is essentially I2R loss occurring inside the core. The current is caused by the induced voltage in any conceivable closed path due to the time varying field as shown in the diagram (A).

Let us consider a thin magnetic plate of length L, height h and thickness τ such that τ is very small compared to both L and h. Also let us assume a sinusoidally time varying field b = Bmaxsinωt exists perpendicular to the rectangular area formed by τ and h as shown in figure (A)

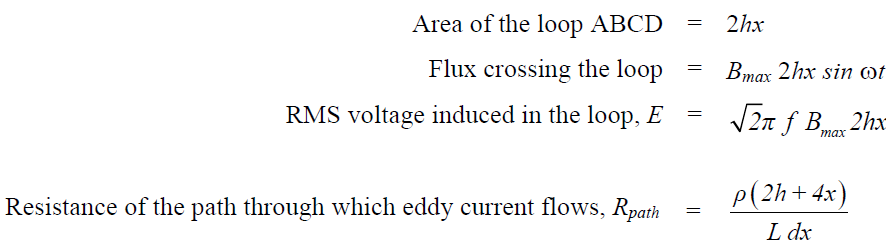

Let us consider a small elemental rectangular closed path ABCDA of thickness dx and at a distance x from the origin. The loop may be considered to be a single coil through which time varying flux is crossing. So there will be induced voltage in it, in similar manner as voltage is induced in a coil of single turn shown in the previous section. Now,

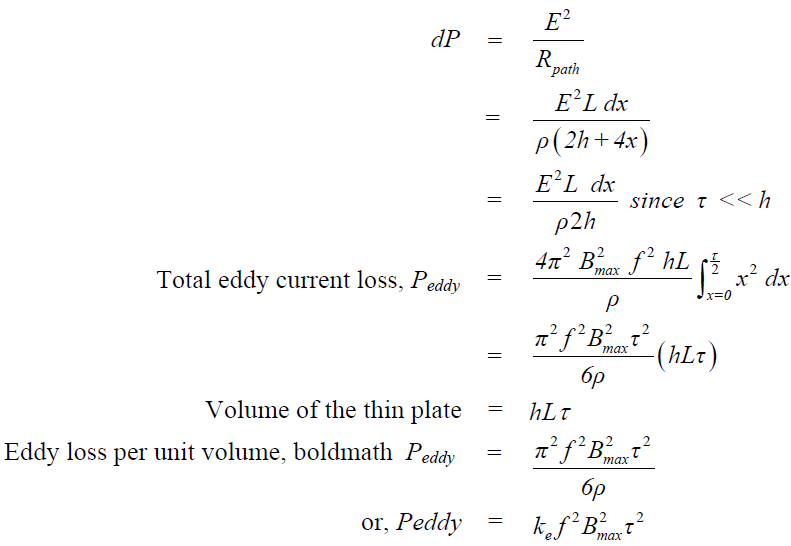

To derive an expression for the eddy current loss in the plate, we shall first calculator the power loss in the elemental strip and then integrate suitably to for total loss. Power loss in the loop dP is given by:

Thus we find eddy current loss per unit volume of the material directly depends upon the square of the frequency, flux density and thickness of the plate. Also it is inversely proportional to the resistivity of the material. The core of the material is constructed using thin plates called laminations. Each plate is given a varnish coating for providing necessary insulation between the plates. Cold Rolled Grain Oriented, in short CRGO sheets are used to make transformer core.