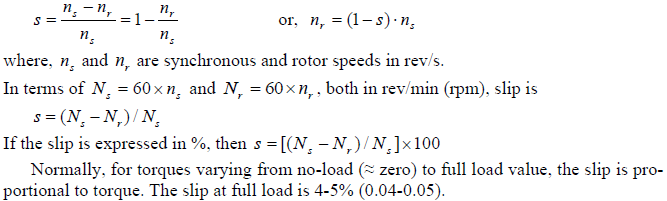

An alternative explanation for the production of torque in a three-phase induction motor is given here, using two rules (right hand and left hand) of Fleming. The stator and rotor, along with air-gap, is shown in Fig. A(a). Both stator and rotor is shown there as surfaces. This is for a section, which is under North pole, as the flux lines move from stator to rotor. The rotor conductor shown in the figure is at rest, i.e., zero speed (stand-still). The rotating magnetic field moves past the conductor at synchronous speed in the clockwise direction. Thus, there is relative movement between the flux and the rotor conductor. Now, if the magnetic field, which is rotating, is assumed to be at standstill as shown in Fig. A(b), the conductor will move in the direction shown. So, an emf is induced in the rotor conductor as per Faraday’s law, due to change in flux linkage. The direction of the induced emf as shown in the figure can be determined using Fleming’s right hand rule.

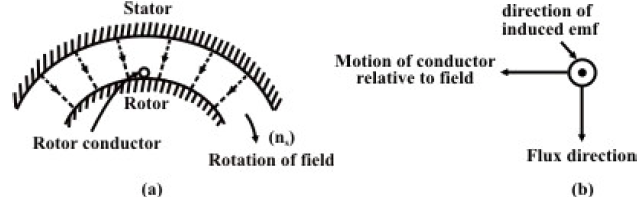

As described earlier, the rotor bars in the cage rotor are short circuited via end rings. Similarly, in the wound rotor, the rotor windings are normally short-circuited externally via the slip rings. In both cases, as emf is induced in the rotor conductor (bar), current flows there, as it is short circuited. The flux in the air gap, due to the current in the rotor conductor is shown in Fig. A(c). The flux pattern in the air gap, due to the magnetic fields produced by the stator windings and the current carrying rotor conductor, is shown in Fig. A(d). The flux lines bend as shown there. The property of the flux lines is to travel via shortest path as shown in Fig. A(a). If the flux lines try to move to form straight line, then the rotor conductor has to move in the direction of the rotating magnetic field, but not at the same speed, as explained earlier. The current carrying rotor conductor and the direction of flux are shown in Fig. A(e). It is known that force is produced on the conductor carrying current, when it is placed in a magnetic field. The direction of the force on the rotor conductor is obtained by using Fleming’s left hand rule, being same as that of the rotating magnetic field. Thus, the rotor experiences a motoring torque in the same direction as that of the rotating magnetic field. This briefly describes how torque is produced in a three-phase induction motor.