Single-phase Induction Motor

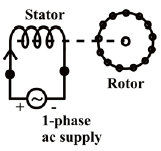

Single-phase Induction Motor: The winding used normally in the stator (Fig. A) of the single-phase induction motor (IM) is a distributed one. The rotor is of squirrel cage type, which is a cheap one, as the rating of this type of motor is low, unlike that for a three-phase IM. As the stator winding is fed from a single-phase supply, the flux in the air gap is alternating only, not a synchronously rotating one produced by a poly-phase (may be two- or three-) winding in the stator of IM. This type of alternating field cannot produce a torque ((To)st=0.0), if the rotor is stationery (ωr=0.0). So, a single-phase IM is not self-starting, unlike a three-phase one. However, as shown later, if the rotor is initially given some torque in either direction (0.0≠rω), then immediately a torque is produced in the motor. The motor then accelerates to its final speed, which is lower than its synchronous speed.

fig(A).Single-phase Induction Motor

fig(A).Single-phase Induction Motor

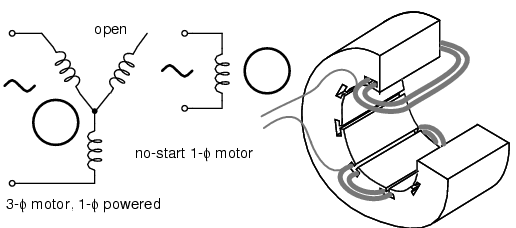

A three phase motor may be run from a single phase power source. (Figure below) However, it will not self-start. It may be hand started in either direction, coming up to speed in a few seconds. It will only develop 2/3 of the 3-φ power rating because one winding is not used.

3-φmotor runs from 1-φ power, but does not start.

3-φmotor runs from 1-φ power, but does not start.

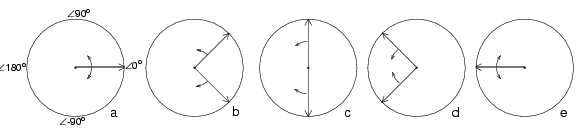

The single coil of a single phase induction motor does not produce a rotating magnetic field, but a pulsating field reaching maximum intensity at 0o and 180o electrical. (Figure below)

Single phase stator produces a nonrotating, pulsating magnetic field.

Another view is that the single coil excited by a single phase current produces two counter rotating magnetic field phasors, coinciding twice per revolution at 0o (Figure above-a) and 180o (figure e). When the phasors rotate to 90o and -90o they cancel in figure b. At 45o and -45o (figure c) they are partially additive along the x axis and cancel along the y axis. An analogous situation exists in figure d. The sum of these two phasors is a phasor stationary in space, but alternating polarity in time. Thus, no starting torque is developed.

However, if the rotor is rotated forward at a bit less than the synchronous speed, It will develop maximum torque at 10% slip with respect to the forward rotating phasor. Less torque will be developed above or below 10% slip. The rotor will see 200% - 10% slip with respect to the counter rotating magnetic field phasor. Little torque (see torque vs slip curve) other than a double freqency ripple is developed from the counter rotating phasor. Thus, the single phase coil will develop torque, once the rotor is started. If the rotor is started in the reverse direction, it will develop a similar large torque as it nears the speed of the backward rotating phasor.

Single phase induction motors have a copper or aluminum squirrel cage embedded in a cylinder of steel laminations, typical of poly-phase induction motors.