Starting Methods For Single-phase Induction Motor

Starting Methods for Single-phase Induction Motor: The single-phase IM has no starting torque, but has resultant torque, when it rotates at any other speed, except synchronous speed. It is also known that, in a balanced two-phase IM having two windings, each having equal number of turns and placed at a space angle of (electrical), and are fed from a balanced two-phase supply, with two voltages equal in magnitude, at an angle of 90° , the rotating magnetic fields are produced, as in a three-phase IM. The torque-speed characteristic is same as that of a three-phase one, having both starting and also running torque as shown earlier. So, in a single-phase IM, if an auxiliary winding is introduced in the stator, in addition to the main winding, but placed at a space angle of 90°(electrical), starting torque is produced. The currents in the two (main and auxiliary) stator windings also must be at an angle of 90°, to produce maximum starting torque, as shown in a balanced two-phase stator. Thus, rotating magnetic field is produced in such motor, giving rise to starting torque. The various starting methods used in a single-phase IM are described here.

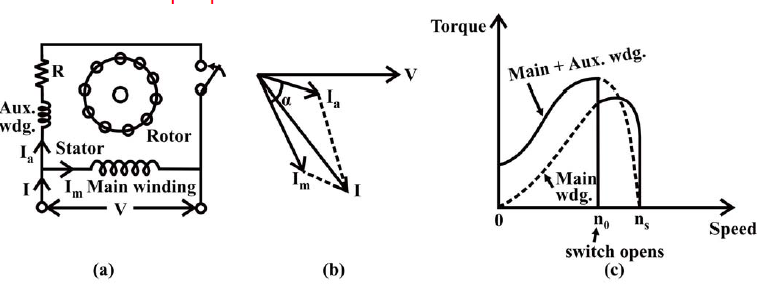

Resistance Split-phase Motor:

fig(A)

The schematic (circuit) diagram of this motor is given in Fig. (A)a. As detailed earlier, another (auxiliary) winding with a high resistance in series is to be added along with the main winding in the stator. This winding has higher resistance to reactance (Ra/Xa) ratio as compared to that in the main winding, and is placed at a space angle of 90° from the main winding as given earlier. The phasor diagram of the currents in two windings and the input voltage is shown in Fig. (A)b. The current (Ia) in the auxiliary winding lags the voltage (Va) by an angle Φa, which is small, whereas the current (Im) in the main winding lags the voltage (V) by an angle, mIφm, which is nearly 90° . The phase angle between the two currents is (90°−aφ), which should be at least 30° . This results in a small amount of starting torque. The switch, S (centrifugal switch) is in series with the auxiliary winding. It automatically cuts out the auxiliary or starting winding, when the motor attains a speed close to full load speed. The motor has a starting torque of 100−200% of full load torque, with the starting current as 5-7 times the full load current. The torque-speed characteristics of the motor with/without auxiliary winding are shown in Fig. (A)c. The change over occurs, when the auxiliary winding is switched off as given earlier. The direction of rotation is reversed by reversing the terminals of any one of two windings, but not both, before connecting the motor to the supply terminals. This motor is used in applications, such as fan, saw, small lathe, centrifugal pump, blower, office equipment, washing machine, etc.