BATIK IN JAVA

Investigation shows that there never was a time when the art of batik did not flourish in Java. The robes of idols worshipped in prehistoric days were decorated very much in the same way as those of today, and apparently the modern native method of doing the work differs little from that employed so many hundreds of years ago. The literal translation from a Javanese paper on the batik art, which concludes this chapter, shows something of the confusingly elaborate process used in the East, while the description of the modern American way of working explains how comparatively simply, effective and beautiful results can be obtained.

The chief difference between the occidental and the native way of batiking is, that the occidental starts his dyeing with the lightest colour and dyes his tones over each other, whilst the native dips his fabric in the darkest colour first and removes the wax each time that he needs a lighter shade and he only uses dyes that set by oxidation. Of course their batiks have to stand very much rougher treatment than the textiles decorated here and to make the dyes stand the terrific glare of the sun, the innumerable washings, and the regular dips taken by their wearers who are tremendously fond of bathing, it is necessary for them to take every precaution to produce fast colours. Their methods may seem complicated, but it would not be amiss if American batikers were to use a little more of the patience and craft that the native exercises, instead of eternally seeking short cuts to superficially beautiful effects.

Batiks are chiefly used in Java for wearing apparel and as a rule are made of calico which is imported from Holland and England, although homespun cotton is occasionally found and was used, of course, before trading with Europe developed almost “Mail Order” facilities.

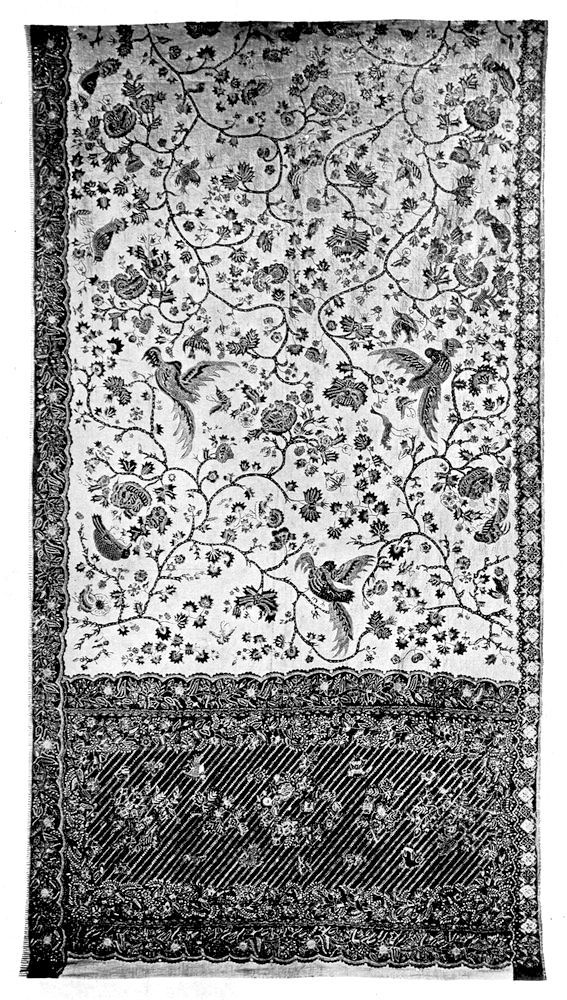

The costume is similar for men and women and consists of the “sarong,” the “slendang” and the “sarong kapala.” There are two types of sarong or loin-cloth worn, which are known as the “kain pandjang” and the “kain kapala”; the former is decorated with an all-over pattern and is used for “every-day” wear, whilst the “kain kapala” is a more expensive form, which besides the all-over pattern, has at one end, from selvedge to selvedge, an elaborate design. There is no intricacy of cutting in a sarong as it consists merely of a piece of material from three to four-and-a-half yards long and about forty-two inches wide. The material used for this garment is almost always cotton of varying grades.

The Javanese sarong facing page 2 is made in four colours, the cream colour of the original material, a bright indigo blue, red, and purple which is the combination of the red and blue. The main part of the sarong is decorated with a flower and bird all-over design, the ground being the cream colour of the material, while the red dominates in the flowers and birds. The wide border has a red background with a cream floral decoration, and the narrow border has a blue background with an ornamental design in cream and red. The kapala of this sarong is in red, with a scattered floral decoration and filled in with a characteristic Javanese filling-in pattern. The purple notes are scattered through the design. Facing page 4 is shown an enlarged detail of this design.

The “slendang” is no more complicated as to shape and the decoration is either in the form of an all-over design, or it has a plain centre with a decorative border. It is usually about three yards long and eighteen inches wide, and it is worn by the women who throw it over their heads, scarf-wise, but its use is more general as a “carry-all” for babies and other personal effects.

The “sarong kapala” is a square piece of material worn chiefly by the men and is wound around the head in a kind of turban shape. After it has been folded on the head to the satisfaction of the wearer, it is taken off very carefully and starched on the inside.

The women sometimes add an upper garment, called a “kemban”; this is just a long straight strip which is wound tightly round the body. The shoulders and arms are left bare, for they are great workers and do not allow their movements to be hampered by an undue amount of clothing.

The designing and waxing of batiks is done largely by the women whilst the men usually take care of the dyeing part of the process. The designs, whilst apparently originating with each individual worker are founded as a rule on what one might call standard designs; these have been used for generations, although in course of time they have changed in character somewhat. In most cases, any one familiar with these Javanese classics can trace the modern designs to their source and will recognize in present-day interpretations, figures well-known in native folk-lore.

Other designs have significance in that they designate rank or social prestige. Some hundred of these patterns have regular names, such as “batik parang rusa” and “batik sawat”; these two are reserved for the exclusive use of royalty, and many designs are esteemed as much for their social ranking as for their artistic merit. Decorated silk is occasionally worn by the native aristocracy; it is not in general use, however, and is always made in the form of a “slendang” and worn as a scarf. The colours found in a batik can be interpreted to denote the part of Java in which it was made. Those from Djocdja and Solo are executed in rich tans, beautiful golden browns and deep indigo blue, which colours are used on the royal batiks; the work from these districts is sombre in tone but very rich in design. Pekalongan batiks are usually in white and different shades of blue, or rather cream and blue, for the native treats his fabric with oil before starting to work and this gives a rich creamy tone to the white. Dead white itself is never used as it is literally associated with the dead, being the colour of grave cloths and always signifying death. Variety of colouring in a batik will mean as a rule that the piece had its origin in the district of Samarang.

The prices of the garments of course vary according to the amount of work on the piece. “Kains” can be bought as cheaply as a dollar each and sometimes as much as $25.00 is paid; however, a batik costing as much is rare, and is usually one made to special order. About two to two and a half dollars is the average price one would have to pay for a garment in Java.

Besides the batik done entirely by hand, the native produces a decorated material known as “tjap.” This method can best be compared to block printing, the wax being printed on to the material instead of being applied with a tjanting. Instead of the wooden block associated with block printing, the native uses a sort of die made of wood, on which the design is made by the insertion, edgewise, of thin strips of brass or red copper; in some cases the whole die is made of the red copper. These “tjaps” are reminiscent of the work done in Madras where a similar process has been employed since the 15th century, for the direct application of the dyes.

Some “tjaps” are done entirely by printing with blocks, while others are partly hand-work. The dies are used as time savers when making borders or patterns with a regular repeat. The native artists consider these substitutes, which are sold to the poorer classes for daily wear, very inferior to real batik and no Javanese of any standing would dream of “lowering himself” by wearing one.

At the present time not many die-makers are found, as there is only a comparatively small market for the work. A die is so solidly constructed and lasts so long, that once made, there is seldom a re-order of the same design. The price of dies varies according to the size and elaborateness of the design, ranging from about 25 cents, American money, to as high as $24.00. In Samarang there are still a few men who trade in these tjaps, whilst in Soerabaja there is only one man known who is able to make them.

The copper used in the making of tjaps comes in three different weights; the lightest is used for the making of fine outlines, the second weight for the heavier lines, whilst the third and heaviest weight is used for the frame work. Like the tjanting, the tjap is constructed in three parts; first, the body of the instrument which is composed of the variously bent strips of copper which make the design, then the frame-work which holds these strips together and lastly the metal handle.

The tjap has to replace the work done with the tjanting, therefore the object of the tjap-maker is to replace all tjanting lines with strips of copper of varying sizes, which, when printed, will give the effect of perfect tjanting work. To that end, the strips of copper have to be curved and bent, and are set in a vertical position, that is, with the edges uppermost; this of course is very delicate work which requires good craftsmanship and much patience.

In making the tjaps, the copper plates of different thicknesses are first cut into strips, each strip of the same width. The design for the tjap is made on paper, and the copper strips are bent in the various shapes as indicated in this design. Here is where the good craftsmanship is essential as it is no easy matter to reproduce fine curved lines with the strips, especially in the case of flowered designs as no sharp angles may be shown in the bending of the copper. Then the whole design is soldered together, and fixed by the same process on to the frame to which the handle is attached.

This does not, however, complete the die-maker’s work, for as in batik work with the tjanting where the material is waxed on both sides, so with the tjap does the fabric have to be printed on the reverse side as well. Thus, the die-maker has to make a second tjap in which the design is the exact reverse of the first one. It takes a die-maker about twenty days to make a complete set, that is two corresponding tjaps, each about eight by eight inches square, for which he gets about $8.00. Out of this of course he has to pay for his materials.

When the tjaps are finished and found correct, that is, when every little line on one die is found to correspond exactly with the same line on the reverse block, then it is the business of the printer to print the tjaps so that no difference is shown in the design. The making of a pair of tjaps is only necessary when an irregular design is to be produced, as in the case of a symmetrical pattern the same die can be used on both sides.

For the reproduction of a not very elaborate tjanting design, a set of thirteen to fifteen tjaps is required; this means with the reverse set at least twenty-six to thirty separate dies. The original outlay for the making of a tjap may be great, but if the amount of work that can be done with one set is considered, it can be seen at once that the prices of pieces done by this process will be very low.

The printing of tjaps is practically always done by men. The workman sits on a low stool, and in front of him is a slanting table to which a large pad is attached; over this the piece that is to be printed is spread. The wax is heated in a flat pan, in which there is a pad of jute, covered with unbleached muslin. The wax is transferred to the metal by pressing the tjap on to this pad. To remove the surplus wax from the tjap the printer swings the die up and down a couple of times and then presses the tjap on to the material in the place where the decoration is desired. After covering one side of the material in this manner, the same process is repeated on the other side. As the wax shines through the fabric, it is not a difficult matter for the printer to place his die in the exact position, so that it will register correctly, but nevertheless, there will be very few pieces made in this way found without a slight inaccuracy in the design. Although all the actual line work in a tjap is done by the use of dies, a certain amount of the work, such as filling in spaces and big surfaces, has to be done by hand with the tjanting. This, however, amounts to a very small proportion of the work when compared with the amount of labour required in the making of a real batik. A good printer can print about twenty pieces of material, sarong length, a day, while it would take twelve to fifteen days to produce one piece of a similar design, with a tjanting.

The European printed imitations of batik meet with very little favour among the native Javanese, who are very critical of art and craftsmanship and the importations only find a market among the poor.

For the most part, batik is a home occupation of the native, but some districts have become quite manufacturing centres. The industry is chiefly under the management of the Chinese with the natives as their workmen. In the district of Lassem, where a great deal of batik work is done, the Chinese employers give the work out to the natives, who do it in their homes. Fifty to a hundred kains will be given out to one man, who will have them waxed and they will then be fetched by another worker who will do the dyeing. This work will bring in to the native, on an average, the lordly sum of two and a half cents (American money) a day, and it is estimated that in the neighbourhood of Lassem alone, there are some 4300 people subsisting on this munificent salary. At that, this group of workers are rather better off than the women who are employed directly by the Chinese for the finer batik work. Large numbers of them bind themselves to work for three years, at the beginning of which period they are given thirty gilders, equivalent to about $12.00; they are given board and lodging and once a year a new outfit, but they receive no more pay. Many of them work like this for years in succession and from time to time they borrow small sums of money from their employers which they cannot pay back, with the result that they are never out of debt and are consequently, to all intents and purposes, practically owned by their exploiters. Authentic figures give 2100 natives working under these conditions in Lassem.

There are a few establishments run by the Dutch in Java, who, besides producing pure native designs, have used native adaptations of European designs with splendid results.

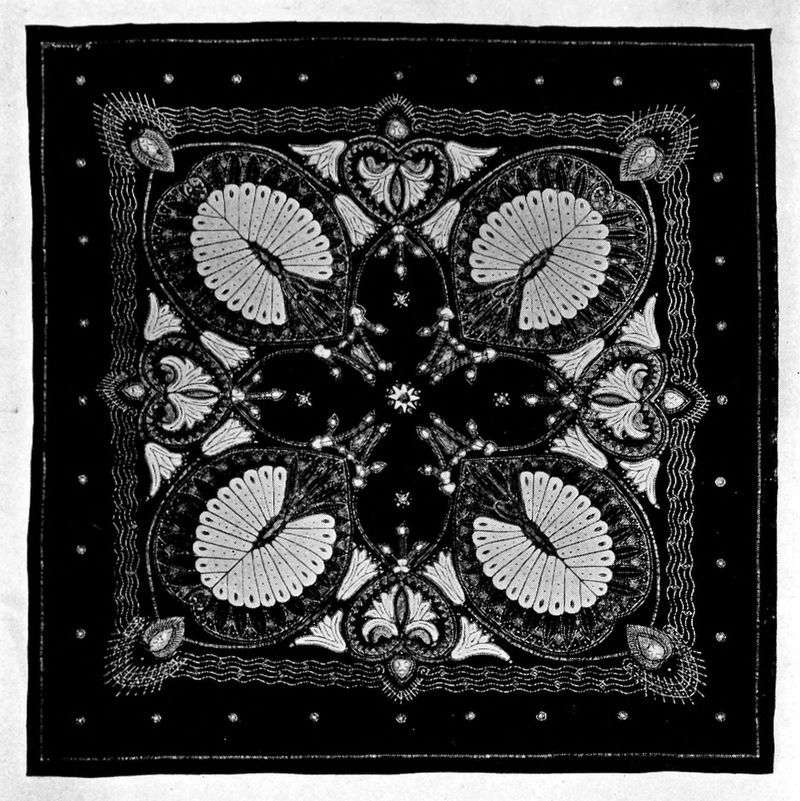

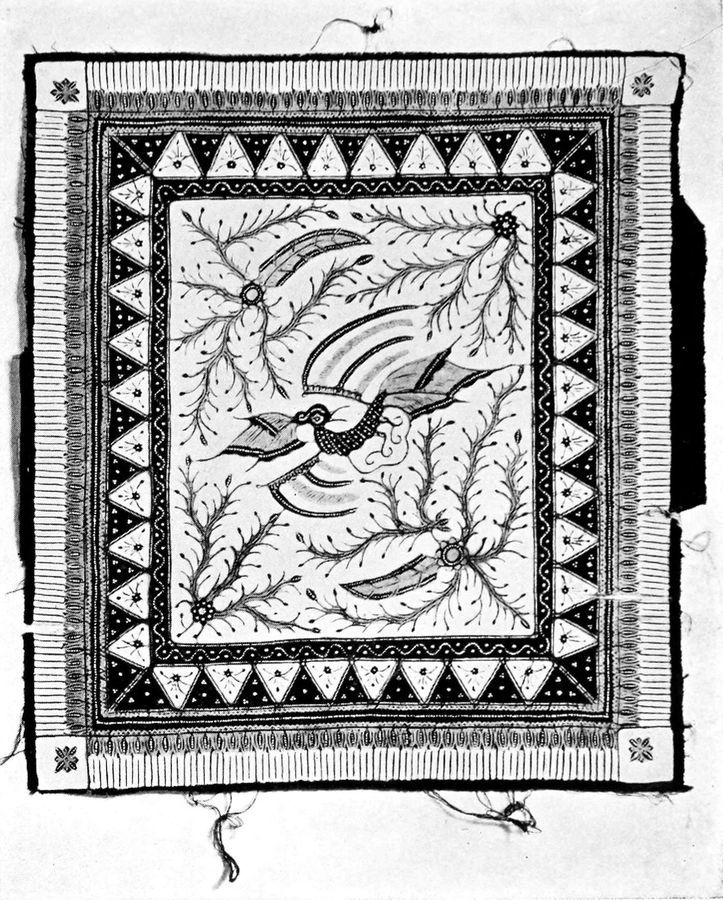

A combination of Javanese and European influences is shown in the illustration facing page 14. This pillow-top, batiked by a Dutch artist, has native motives, arranged in a symmetrical design. As a batik, it is about the finest piece the writer has been able to find, as there is no flaw in the execution. The stiff geometrical pattern, however, does not give quite such a pleasing effect as the freer Javanese design. A sample of this is shown facing page 14 which is pure Javanese decoration. It shows the arrangement of a bird and some octopuses and was used for a small pillow-top; the artist has been left free in this design, not being tied down to a geometrical repeat, and the result artistically is far superior to the previous design.

In the event of some enthusiast wishing to batik in the actual native manner, he can do so by following the process as described by a native and translated here word for word:—

“Batik is the art of dyeing fabric in one piece in different dyes consecutively, through the combination of which the pattern of the design is produced. The materials used in this process are cotton and very occasionally silk, wax, wax mixed with rosin and dyes. The dyes usually are vegetable although aniline is used, but rarely.

“The first of these batik requirements the native buys at the Pasar (market), the dyes they make themselves and in the case of the blue dye it is as a rule the property of a professional dyer, who is called the ‘toekang medel.’

“The cotton used now by batikers is always of European manufacture and is graded according to the fineness of the texture. The different qualities are known severally as, ‘mori moeslim’ or fine-weave cotton, ‘mori mentah’ or unbleached cotton, and ‘mori kasar’ or coarse-weave cotton. The second grade is subdivided into ‘mori mentah aloes’ which is the fine grade of the unbleached cotton and ‘mori mentah kasar’ or coarse unbleached. This last kind is only used by the native aristocracy for the clothing of the members of their household; they themselves wear batik of ‘mori moeslim’ or ‘mori mentah aloes.’

“The measure used when cotton is bought at the ‘Pasar’ is called ‘katja’ or ‘saptangnan’ and it is a square measure, that is to say, if, for instance, the cloth is a yard wide then the measure or ‘katja’ is a yard square and if the width is a yard and a half, the ‘katja’ is a yard and a half.

“The cotton as it comes from the market is not immediately ready to be batiked. If it is a bleached cotton it has to be treated for the removal of all the starch, chalk and other stiffening with which it is dressed. This is done by washing it several times in clear cold water. It is then soaked for several days in cocoanut oil; this in its turn is boiled out in water containing the ashes of burnt rice stalks; this process is continued till the fabric is free from oil. This soaking and boiling is always done, whether the material is bleached or unbleached, and is called ‘mateng’ which literally translated means ‘done’ or cooked thoroughly.

“After the piece is dried in the sun, the cut edges are hemmed—‘didjilid.’ Now the material has to be starched again, ‘njekoeli’; this stiffening is to prevent the wax from flowing too freely,—a condition known as ‘mresep.’ The rice water that is used for this, is made from a strained rice gruel, or more simply, the water is used in which the rice has been boiled. After the material has been starched it is ‘dipe’ or dried once more in the sun and it is then rolled up. This roll is laid on a wooden board, ‘kemplomgen’ and pounded with a wooden hammer, ‘gandeng,’ or if a hammer is not available, the wooden rice pestle, ‘aloe’ can be used. This process is called ‘nganplongi’ and is to make the material soft and supple. Now the material is ready to be batiked, and the following materials and tools are needed.

“1. Wax. Usually six parts of ‘melam geplak’ and one part ‘melam poetih’ are used, with sometimes the addition of a little ‘melam ireng.’ The ‘melam geplak’ consists of a mixture of ‘damar mata koetjing’ which is a kind of rosin that comes from Borneo, melted with animal fat. The ‘melam poetih’ is pure bees-wax and the ‘melam ireng’ is dark coloured wax which has been used already in a previous batik and which has become dark from the blue dye which it took up when in the blue-dye bath. The first two kinds of wax can be bought at any market, but not the ‘melam ireng,’ as every one who batiks always saves enough dark wax from former work, or in case of need, a neighbour will always lend some.

“2. A pan called ‘wadjan’ in which to melt the wax. This is generally of iron, though poor people use stone pots.

“3. A little copper instrument called ‘tjanting’ used in drawing with the wax on the material. It is made of fine thin red copper and has one or more little spouts and a bamboo handle. These tjanting have different names according to the type of work for which they are used, (a) Tjanting ‘isen isen’; this has a very slender spout and is used to make very fine lines and little dots, (b) Tjanting ‘kjandangen’: this instrument has a larger spout and is used to wax the parts which have to stay white in the first process, (c) Tjanting ‘penangang’; this is the tjanting used to cover up the bigger surfaces, (d) The ‘penembok’ has a very wide spout to cover parts that are to be completely protected by wax, (e) The tjanting ‘pengada’ has two spouts next each other for the drawing of parallel lines. There are various other varieties that have three, five and sometimes as many as six spouts for making little rosettes and groups of dots. Tjantings are always made by men and the work is not subdivided, that is to say, one man makes the instrument from start to finish; as a rule the makers have at least twenty-five tjanting in the course of construction at the same time. It takes a good workman six to seven days to make about 250 of the little tools, that is, about forty a day. Figuring the cost of materials and charcoal used in the making, together with overhead expenses and the receipts figuring at the rate of 24 cents (American money), for 240 tjantings, it will be seen that an excellent craftsman makes on an average about 30 cents in Dutch money, equivalent to 12 cents American, a day.

“4. The ‘djegoel,’ an instrument which replaces the brush used in Europe and is made of a thin wooden stick with a wad of cotton tied to the end. This is for waxing very large surfaces.

“5. The ‘iroes.’ This is a spoon made out of cocoanut shell and has a bamboo handle; it is used to mix the melted wax and to scoop the wax off the water in which the finished batik has been boiled.

“6. The ‘wadja.’ The copper pan in which the fabric is boiled when the wax is being removed.

“7. The ‘panjawanjan.’ A small movable stand over which the material is hung during the waxing process.

“8. The ‘tjawang.’ A small bamboo clip used to fasten the fabric to the stand. Rich batikers use an iron clip called “bandoel.”

“9. The ‘doelang.’ A large wooden trough for dyeing.

“10. The ‘pane.’ A small vessel also used for dye made of wood, copper, or earthenware.

“11. The ‘blebeo.’ A wooden straight-edge for use when drawing straight lines—a process called ‘batikan garisan.’

“12. The ‘semprong.’ A blow-pipe with which to blow the fire. The fire is made, as a rule, between three stones set in the form of a triangle, upon which the wax pot is placed.

“To do real batik work the proceedings are as follows. First the main outline of the design is sketched on the material, with charcoal or pencil, and when this is completed the fabric is hung over the little stand and with the tjanting the design is drawn in with wax, the material meanwhile being supported with the left hand; the worker sits on a little mat in front of her stand. The finer parts of the pattern are drawn in without pencil guiding lines.

“When one side is decorated the piece is turned around and the back is very carefully drawn in. With all the surfaces covered which are not intended to be blue it is ready for the blue dye-bath. This dyeing in blue is done by the batiker herself or more often by the professional blue-dyer who does it for a small remuneration. If red is planned on the batik, the wax is removed from the places where this colour is wanted by sponging with hot water. The material is then re-starched with rice water, aren sugar and pulverized randoe leaves, so that the wax will not run or become soft. The parts that are to remain blue have to be re-covered with wax and the piece is ready for the red dye.

“This red dye is made from an infusion of soga bark; successive dippings are made until the desired colour is obtained. To make the colour permanent and at the same time to obtain the much desired purple glow, the material is dipped in a bath made of a mixture of Java sugar, whiting, and alum. It is left in this solution for about an hour, after which it is well rinsed and transferred to a hot water bath. The water is boiled and the wax is dissolved; the wax floating on the top of the water is collected for further use. The finished batik is then dried in the sun. If other colours are required on the piece the same program is repeated.”