THE VALUE OF A DYE RECORD

A dye record is an invaluable asset to a batiker; it is very little trouble to make and the time spent on it will easily be saved when future work is to be speeded up or samples are being made. A record book will prove its value in many ways, particularly if the batiks made are liable to be re-ordered, as for instance, when gowns are decorated for the trade, or if the making of one batik leads to a demand for a second, which perhaps is wanted with the same colour effects although not the same design. It is a good plan, therefore, to leave an extra strip of material on the piece that is to be batiked, or to pin a piece to the fabric which is to be decorated and let it go through all the different baths and processes, each time taking off a small sample of the new colour to be pasted in the record book.

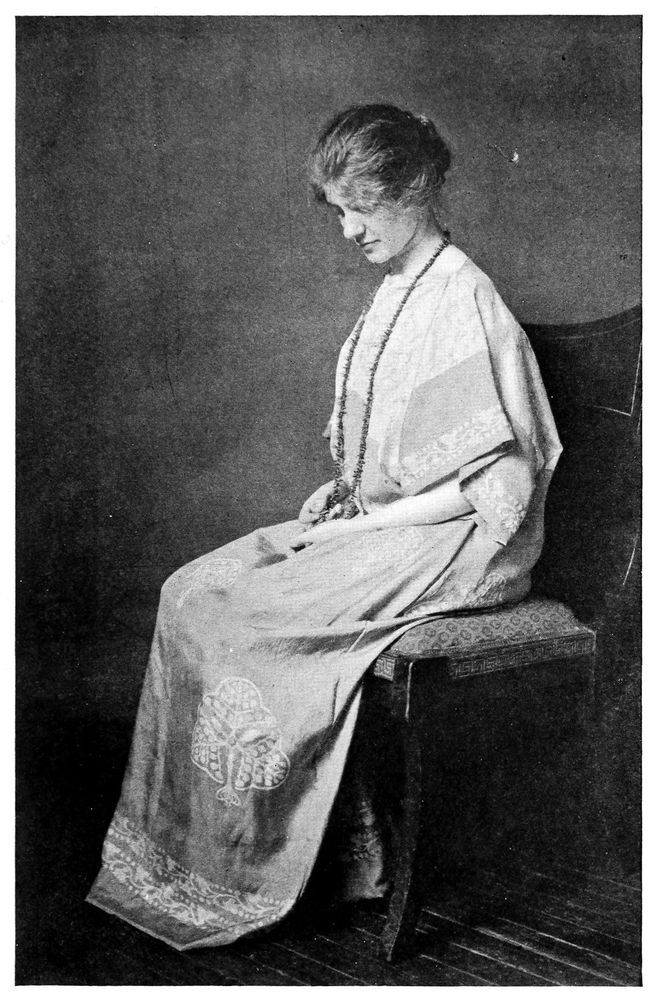

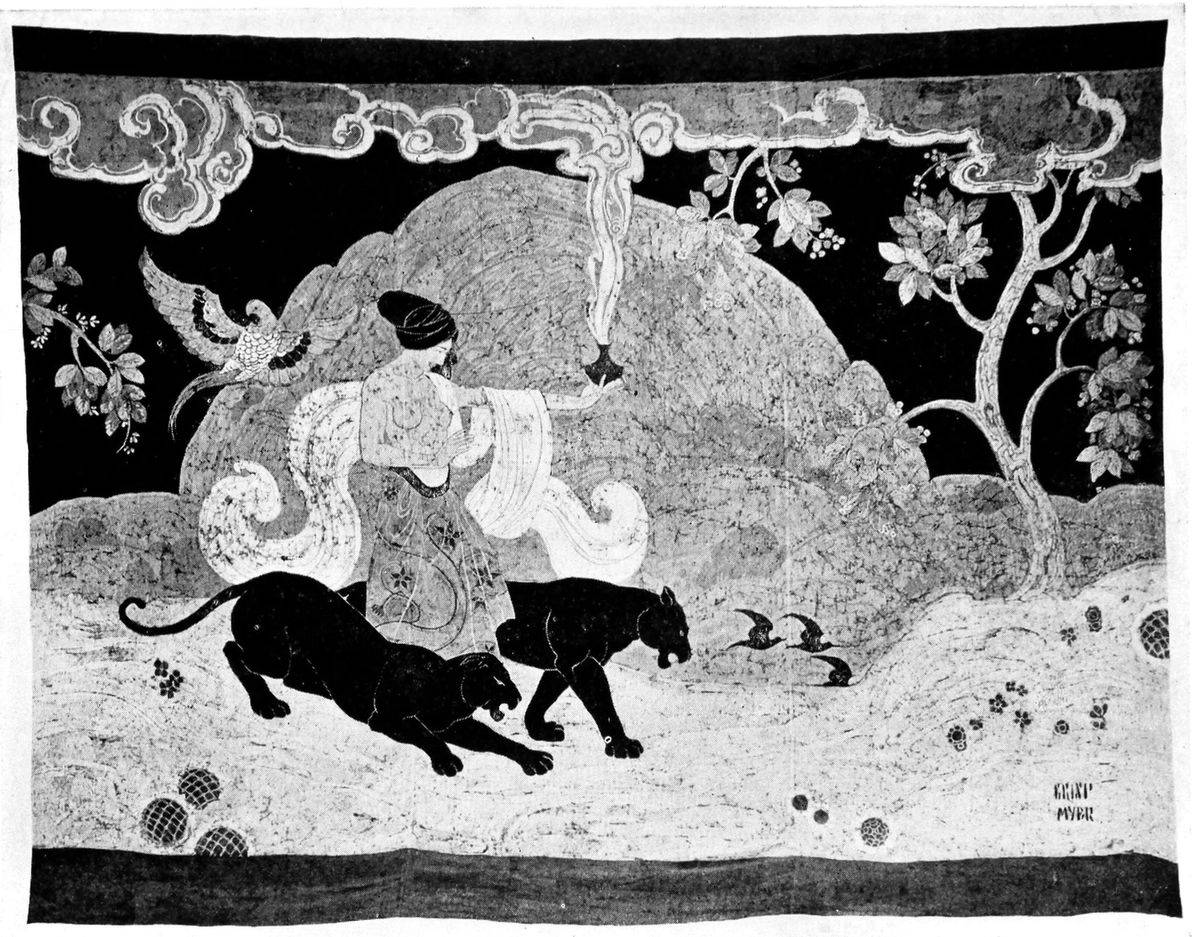

Design, “Sorceress.”—Designer, A. Crisp. Batiked by P. Mijer and A. Crisp.

Date, January 2nd, 1918.

No. |

Sample |

Temp. |

Color |

Time in bath |

Acid |

Remarks |

|---|---|---|---|---|---|---|

| 1 | White | 105-110 | Yellow cream | 20 min. | Acetic | |

| 2 | Yellow cream | 110 | Salmon pink | 20 min. | Acetic | |

| 3 | Flesh colour | 110 | Light blue | 15 min. | Acetic | |

| 4 | Grey-blue | 105 90 |

Strong blue | 20 min. 20 min. |

Slight crackle obtained by reduction of temperature. |

|

| 4a | Blue | 100 | Bleach | 15-20 min. | Ammonia | The batik is dipped in ammonia and rinsed for an hour. |

| 5 | Grey | 110 | Gold | 40 min. | Acetic | |

| 6 | Gold | 110 | Blue | 60 min. | Acetic | |

| 7 | Bluish-gold | 110 | Red | 50 min. | Acetic | |

| 9 | Bordeau | 90 110 |

Black Blue |

60 min. 60 min. |

Blue added to improve tone of black. |

|

| 10 | Black | Material used, crepe-de-Chine. Price per yd., $5.00. Length of piece, 13 ft., 4 in. Height of piece, 9 ft. Gasoline, 15 gallons. (3 baths). Beeswax, 5 lbs. |

||||

As will be seen from the record quoted here, every detail is marked down—the temperature, time of dyeing, price of material and where it was bought, in fact any little item that may be of help later. A full explanation of this sample page may be of service to some readers.

The record shows the process of dyeing in the making of the “Sorceress” panel, shown facing page 78. The silk used for this panel was a very heavy Japanese crepe and the design was worked out in nine colours. That is to say, it was dipped eight times, the ninth being the original white of the silk. The only places where this original white shows is in a few little flowers in the branches of the trees, and these, on account of the many times the piece was dyed, have so much crackle in them that they do not appear as pure white.

The piece was first dyed a very light creamy yellow colour; this tone being composed of yellow, a speck of blue and a speck of orange. The mixture of these colours produces gold and a much diluted solution results in a straw yellow. The temperature for this bath was between 105° and 110° Fahr., and the time for dyeing about twenty minutes. After having been rinsed and dried, the parts of the design that were wanted the straw colour were covered in wax, the largest surface being the scarf of the Sorceress.

The panel was now ready for the second dipping. This was a light salmon pink, which over the straw-yellow gave the flesh colour for the face and body; this tone also appears in the light outline of the smoke and clouds. This salmon colour was made of orange and yellow mixed and was used very light. Temperature 110°; time, about 20 minutes.

The third bath was blue. This was used in the mountain in the background and in some of the leaves in the foreground on the piece. The blue was used pure, but not very strong. With the flesh colour, this gave a greyish blue. Temperature 110°. Time 15 minutes.

The fourth colour was the same blue, only much stronger, and in this the trees in the mountain, the outlines of the mountain and the stems of the bigger leaves were dyed. The fabric was in this bath altogether about 40 minutes. The first half of this period the temperature of the dye was about 105° and was reduced to 90° for the last twenty minutes. This difference in the temperature was made in order to make the wax brittle and obtain a slight crackle to allow the penetration of the colour.

The crackle effect was not desired all over the design, so a second covering of wax was applied in some parts, after the material had been thoroughly dried. The face and body of the figure, in particular, were carefully gone over, as these parts had to remain as little as possible affected by the darker colours.

The panel was now dipped in an ammonia bath to extract the colour from the parts not covered by wax. This took from 15 to 20 minutes with a temperature of 100° Fahr. When the colour in the fabric was reduced to a light grey, the piece was transferred from the ammonia bath to a tub of clear water at the same temperature, and rinsed thoroughly for at least an hour, in order to remove every trace of the ammonia. After drying, the whole panel was carefully gone over to close all undesired cracks that had come during the colour extracting process; these were mainly in the figure and the scarf.

No grey was used in the panel, therefore after the filling in of the cracks, the piece was ready for the fifth bath. This was the gold used for the foreground, and it also makes the high-lights in the leaves and in the tree-trunks. This gold was obtained by mixing yellow, orange and blue, with the yellow as the dominant colour. Temperature, 110°. Time, 40 minutes. The sixth bath was the same gold solution, strengthened up with blue but without the addition of any more orange or yellow. This colour was used in the leaves, some parts of the trees, the wings of the parrot and the solid colour of the skirt. Temperature, 110°. Time, 60 minutes.

The seventh dipping was red (roccelline). This colour was used pure and over the blueish gold of the previously dyed colours, it appeared a deep rich red, almost a bordeau. The turban, the vase, parts of the parrot’s wings, the flowers in the foreground and the borders at the top and bottom of the panel are all in this tone. Temperature, 110°. Time, 50 minutes. After waxing all these parts, the other covered parts were inspected once more and all damaged places and objectionable cracks repaired; this completed, the panel was ready for the eighth and final bath, black.

At this stage the only parts of the whole design that were not covered in wax, were, the sky, a small part of the turban, the two panthers and the three little birds in the centre foreground.

The black was started pure, at a temperature of about 90°, and the piece remained in this bath about an hour; it was then taken out, the temperature brought up to 110°, blue added to the solution and the panel again dipped for another hour. The blue was added in order to improve the tone of the black. A solid blue-black was obtained in this way in place of the rusty black that would have been the result of dyeing straight black over the red. After the required intensity of tone had been reached, the piece was well rinsed and dried, preparatory to dipping in gasoline to remove the wax.

The making of this piece took about four weeks, exclusive of the time taken to prepare the original sketch or the full-size cartoon.

About five pounds of pure bees-wax was used to cover all the surfaces, and fifteen gallons of gasoline were necessary to clean the piece. This is not surprising when one realizes the size of the panel, which was eight feet high and thirteen feet four inches wide; in all, 15,360 square inches.