Control System Design

CONTROL SYSTEM DESIGN

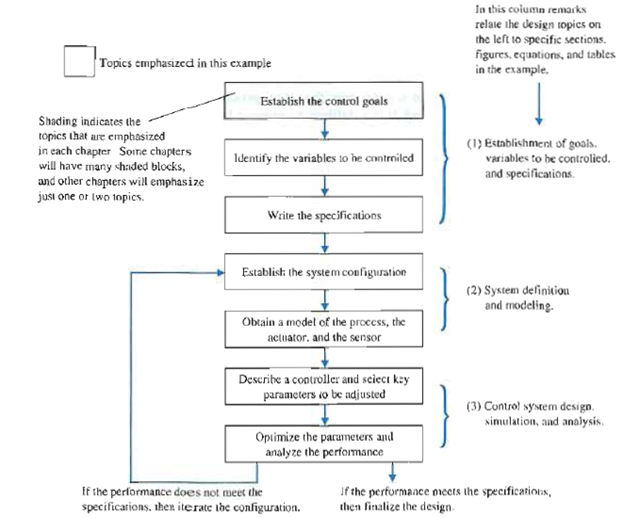

The design of control systems is a specific example of engineering design. The goal of control engineering design is to obtain the configuration, specifications, and identification of the key parameters of a proposed system to meet an actual need. The control system design process is illustrated in Figure 1. The design process consists of seven main building blocks, which we arrange into three groups:

1. Establishment of goals and variables to be controlled, and definition of specifications (metrics) against which to measure performance

2. System definition and modeling

3. Control system design and integrated system simulation and analysis

The objective is to demonstrate different aspects of the design process through illustrative examples. The design process block diagram are:

1. Establishment of goals, control variables, and specifications

2. System definition and modeling

3. Control system design, simulation, and analysis

The first step in the design process consists of establishing the system goals. For example, we may state that our goal is to control the velocity of a motor accurately. The second step is to identify the variables that we desire to control (for example, the velocity of the motor). The third step is to write the specifications in terms of the accuracy we must attain. This required accuracy of control will then lead to the identification of a sensor to measure the controlled variable. The performance specifications will describe how the closed-loop system should perform and will include

(1) good regulation against disturbances,

(2) desirable responses to commands,

(3) realistic actuator signals,

(4) low sensitivities, and

(5) robustness.

As designers, we proceed to the first attempt to configure a system that will result in the desired control performance. This system configuration will normally consist of a sensor, the process under control, an actuator, and a controller. The next step consists of identifying a candidate for the actuator. This will, of course, depend on the process, but the actuation chosen must be capable of effectively adjusting the performance of the process. For example, if we wish to control the speed of a rotating flywheel, we will select a motor as the actuator. The sensor, in this case, must be capable of accurately measuring the speed. We then obtain a model for each of these elements. The next step is the selection of a controller, which often consists of a summing amplifier that will compare the desired response and the actual response and then forward this error-measurement signal to an amplifier. The final step in the design process is the adjustment of the parameters of the system to achieve the desired performance. If we can achieve the desired performance by adjusting the parameters, we will finalize the design and proceed to document the results. If not, we will need to establish an improved system configuration and perhaps select an enhanced actuator and sensor. Then we will repeat the design steps until we are able to meet the specifications, or until we decide the specifications are too demanding and should be relaxed.