Ac Induction Tachometer

AC Induction Tachometer

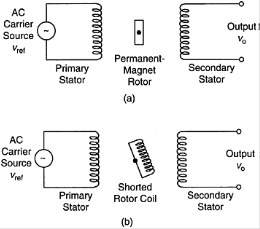

This tachometer is similar in construction to a two-phase induction motor. The stator arrangement is identical to that of the ac permanent-magnet tachometer, as presented before.

The rotor has windings, which are shorted and not energized by an external source, as shown in Figure (b). One of the stator windings is powered by an ac supply.

This induces a voltage in the rotor windings, and it is a modulated signal. The high-frequency (carrier) component of this induced signal is due to the direct transformer action of the primary ac.

The other (modulating) component is induced by the speed of rotation of the rotor, and its magnitude is proportional to the speed of rotation.

The no energized stator (secondary) winding provides the output of the tachometer. This voltage output is a result of both the stator (primary) windings and the rotor windings.

As a result, the tachometer output has a carrier ac component whose frequency is the same as the primary signal frequency, and a modulating component, which is proportional to the speed of rotation.

Demodulation would be needed to extract the component that is proportional to the angular speed of the rotor. The main advantage of ac tachometers over their conventional dc counterparts is the absence of slip-ring and brush devices, since the output is obtained from the stator.

In particular, the signal from a dc tachometer usually has a voltage ripple, known as the commutator ripple or brush noise, which are generated as the split ends of the slip ring pass over the brushes, and as a result of contact bounce, etc. The frequency of the commutator ripple is proportional to the speed of operation; consequently, filtering it out using a notch filter is difficult (a speed tracking notch filter would be needed).

Also, there are problems with frictional loading and contact bounce in dc tachometers, and these problems are absent in ac tachometers. Note, however, that a dc tachometer with electronic commutation does not use slip rings and brushes. But they produce switching transients, which are undesirable.

As for any sensor, the noise components will dominate at low levels of output signal. In particular, since the output of a tachometer is proportional to the measured speed, at low speeds, the level of noise, as a fraction of the output signal, can be large.

Hence, removal of noise takes an increased importance at low speeds.

It is known that at high speeds the output from an ac tachometer is somewhat nonlinear (primarily due to the saturation effect).

Furthermore, signal demodulation is necessary, particularly for measuring transient speeds.

Another disadvantage of ac tachometers is that the output signal level depends on the supply voltage; hence, a stabilized voltage source, which has a very small output-impedance, is necessary for accurate measurements.