Analog-digital Conversion

Analog-Digital Conversion

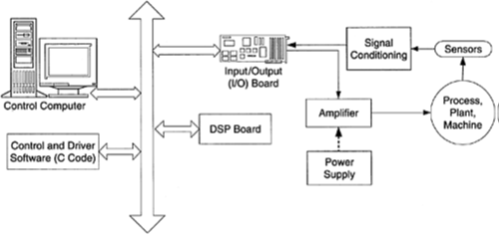

Mechatronic systems use digital data acquisition for a variety of purposes such as process condition monitoring and performance evaluation, fault detection and diagnosis, product quality assessment, dynamic testing, system identification (i.e., experimental modeling), and feedback control.

Typically, the measured responses (outputs) of a physical system (process, plant) are available in the analog form, as a continuous signal (function of continuous time).

Furthermore, typically, the excitation signals (or control inputs) for a physical system have to be provided in the analog form.

A digital computer is an integral component of a modern control system; particularly a mechatronic system, and is commonly incorporated in the form of microprocessors and single-board computers together with such components as digital signal processors (DSP).

In a mechatronic system, a digital computer will perform tasks such as signal processing, data analysis and reduction, parameter estimation and model identification, decision-making, and control.

Inputs to a digital device (typically, a digital computer) and outputs from a digital device are necessarily present in the digital form.

Hence, when a digital device is interfaced with an analog device, the interface hardware and associated driver software have to perform several important functions.

Two of the most important interface functions are digital to analog conversion (DAC) and analog to digital conversion.

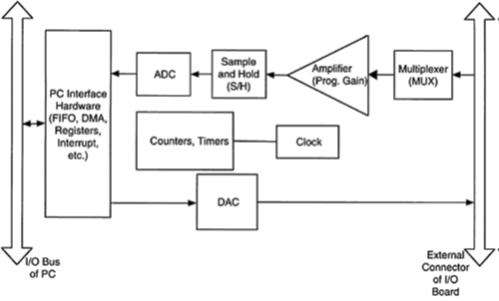

A digital output from a digital device has to be converted into the analog form for feeding into an analog device such as actuator or analog recording or display unit. Also, an analog signal has to be converted into the Main components of an I/O board of a PC.