Bridge Sensitivity

Bridge Sensitivity

Strain gage measurements are calibrated with respect to a balanced bridge. When the strain gages in the bridge deform, the balance is upset.

If one of the arms of the bridge has a variable resistor, it can be changed to restore balance. The amount of this change measures the amount by which the resistance of the strain gages changed, thereby measuring the applied strain. This is known as the null-balance method of strain measurement.

This method is inherently slow because of the time required to balance the bridge each time a reading is taken. A more common method, which is particularly suitable for making dynamic readings from a strain gage bridge, is to measure the output voltage resulting from the imbalance caused by the deformation of active strain gages in the bridge.

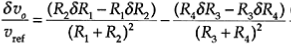

To determine the calibration constant of a strain gage bridge, the sensitivity of the bridge output to changes in the four resistors in the bridge should be known.

For small changes in resistance, using straightforward calculus, this may be determined as

Early strain gages were fine metal filaments. Modern strain gages are manufactured primarily as metallic foil (e. g., using the copper-nickel alloy known as constantan) or semiconductor elements (e.g., silicon with trace impurity boron).

They are manufactured by first forming a thin film (foil) of metal or a single crystal of semiconductor material and then cutting it into a suitable grid pattern, either mechanically or by using photo etching (opto-chemical) techniques. This process is much more economical and is more precise than making strain gages with metal filaments. The strain gage element is formed on a backing film of electrically insulated material (e.g., polymide plastic).

This element is cemented or bonded using epoxy, onto the member whose strain is to be measured. Alternatively, a thin film of insulating ceramic substrate is melted onto the measurement surface, on which the strain gage is mounted directly. The direction of sensitivity is the major direction of elongation of the strain gage element.

To measure strains in more than one direction, multiple strain gages (e.g., various rosette configurations) are available as single units.