Improvement Of Operating Properties

Improvement of Operating Properties

By applying active feedback control, precision is obtained not only through the high mechanical precision of a passively feed forward controlled mechanical element, but by comparison of a programmed reference variable and a measured control variable.

Therefore, the mechanical precision in design and manufacturing may be reduced somewhat and simpler constructions for bearings or sideways can be used.

An important aspect is the compensation of a larger and time variant friction by adaptive friction compensation.

Also, a larger friction on cost of backlash may be intended (such as gears with pretension), because it is usually easier to compensate for friction than for backlash. Model-based and adaptive control allow for a wide range of operation, compared to fixed control with unsatisfactory performance (danger of instability or sluggish behavior). A combination of robust and adaptive control allows a wide range of operation for flow-, force-, or speed-control, and for processes like engines, vehicles, or aircraft.

A better control performance allows the reference variables to move closer to the constraints with an improvement in efficiencies and yields (e.g., higher temperatures, pressures for combustion engines and turbines, compressors at stalling limits, higher tensions and higher speed for paper machines and steel mills).

Addition of New Functions

Mechatronic systems allow functions to occur that could not be performed without digital electronics.

First, no measurable quantities can be calculated on the basis of measured signals and influenced by feed forward or feedback control.

Examples are time-dependent variables such as slip for tyres, internal densities, temperatures, slip angle and ground speed for steering control of vehicles, or parameters like damping, stiffness coefficients, and resistances.

The adaptation of parameters such as damping and stiffness for oscillating systems (based on measurements of displacements or accelerations) is another example.

Integrated supervision and fault\ Diagnosis becomes more and more important with increasing automatic functions, increasing complexity, and higher demands on reliability and safety.

Then, the triggering of redundant components, system reconfiguration, maintenance-on-request, and any kind of teleservice

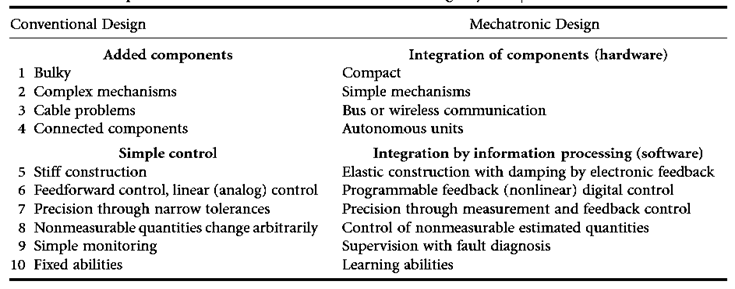

Properties of Conventional and Mechatronic Design Systems: