Loading Considerations

Loading Considerations

The torque required to drive a tachometer is proportional to the current generated (in the dc output). The associated proportionality constant is the torque constant.

With consistent units, in the case of ideal energy conversion, this constant is equal to the voltage constant. Since the tachometer torque acts on the moving object whose speed is measured, high torque corresponds to high mechanical loading, which is not desirable.

Hence, it is needed to reduce the tachometer current as much as possible. This can be realized by making the input impedance of the signal-acquisition device (i.e., hardware for voltage reading and interface) for the tachometer as large as possible.

Furthermore, distortion in the tachometer output signal (voltage) can result because of the reactive (inductive and capacitive) loading of the tachometer. When dc tachometers are used to measure transient velocities, some error will result from the rate (acceleration) effect.

This error generally increases with the maximum significant frequency that must be retained in the transient velocity signal, which in turn depends on the maximum speed that has to be measured. All these types of error can be reduced by increasing the load impedance.

For illustration, consider the equivalent circuit of a tachometer with an impedance load ZL connected to the output port of the armature circuit.

The induced voltage Kwi is represented by a voltage source. Note that the constant K depends on the coil geometry, the number of turns, and the magnetic flux density.

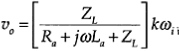

Coil resistance is denoted by Ra, and leakage inductance is denoted by La. The load impedance is ZL. From straightforward circuit analysis in the frequency domain, the output voltage at the load is given by