Microprocessors And Microcontrollers

Microprocessors and Microcontrollers:

There is no strict border between microprocessors and microcontrollers because certain chips can access external code and/or data memory (microprocessor mode) and are equipped with particular peripheral components.

Some microcontrollers have an internal RC oscillator and do not need an external component. However, an external quartz or ceramic resonator or RC network is frequently connected to the built-in, active element of the clock generator.

Clock frequency varies from 32 kHz (extra low power) up to 75 MHz Another auxiliary circuit generates the reset signal for an appropriate period after a supply is turned on. Watchdog circuits generate chip reset when a periodic retriggering signal does not come in time due to a program problem.

There are several modes of consumption reduction activated by program instructions. Complexity and structure of the interrupt system (total number of sources and their priority level selection), settings of level/edge sensitivity of external sources and events in internal (i.e., peripheral) sources, and handling of simultaneous interrupt events appear as some of the most important criteria of microcontroller taxonomy.

Although 16- and 32-bit microcontrollers are engaged in special, demanding applications (servo-unit control), most applications employ 8-bit chips. Some microcontrollers can internally operate with a 16-bit or even 32-bit data only in fixed-point range—microcontrollers are not provided with floating point unit (FPU).

New microcontroller families are built on RISC (Reduced Instruction Set) core executing due to pipelining one instruction per few clock cycles or even per each cycle.

Programmable Logic Controllers

A programmable logic controller (PLC) is a microprocessor-based control unit designed for an industrial installation (housing, terminals, ambient resistance, and fault tolerance) in a power switchboard to control machinery or an industrial process. It consists of a CPU with memories and an I/O interface housed either in a compact box or in modules plugged in a frame and connected with proprietary buses.

The compact box starts with about 16 I/O interfaces, while the module design can have thousands of I/O interfaces. Isolated inputs usually recognize industrial logic, 24 V DC or main AC voltage, while outputs are provided either with isolated solid state switches (24 V for solenoid valves and contactors) or with relays.

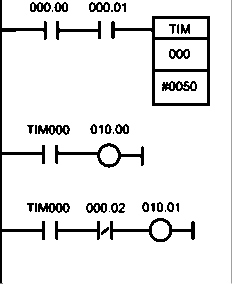

Screw terminal boards represent connection facilities, which are preferred in PLCs to wire them to the controlled systems. I/O logical levels can be indicated with LEDs near to terminals. Since PLCs are typically utilized to replace relays, they execute Boolean (bit, logical) operations and timer/counter functions (a finite state automaton). Analog I/O, integer or even floating point arithmetic, PWM outputs, and RTC are implemented in up-to-date PLCs. A PLC works by continually scanning a program, such as machine code, that is interpreted by an embedded microprocessor (CPU). The scan time is the time it takes to check the input status, to execute all branches (all individual rungs of a ladder.