Rotary Potentiometers

Rotary Potentiometers

Potentiometers that measure angular (rotatory) displacements are more common and convenient, because in conventional designs of rectilinear (translatory) potentiometers, the length of the resistive element has to be increased in proportion to the measurement range or stroke.

Presents schematic representations of translatory and rotatory potentiometers. Helix-type rotatory potentiometers are available for measuring absolute angles exceeding 360°.

The same function may be accomplished with a standard single cycle rotatory pot simply by including a counter to record full 360° rotations.

Note that angular displacement transducers, such as rotatory potentiometers, can be used to measure large rectilinear displacements on the order of 3 m.

A cable extension mechanism may be employed to accomplish this. A light cable wrapped around a spool, which moves with the rotary element of the transducer, is the cable extension mechanism.

The free end of the cable is attached to the moving object, and the potentiometer housing is mounted on a stationary structure. The device is properly calibrated so that as the object moves the rotation= count and fractional rotation measure will directly provide the rectilinear displacement.

A spring-loaded recoil device, such as a spring motor, will wind the cable back when the object moves toward\ the transducer.

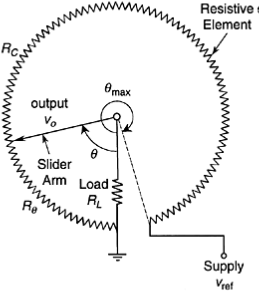

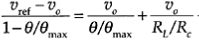

Loading Nonlinearity

Consider the rotatory potentiometer shown in Figure 6.3. Let us now discuss the significance of the “loading nonlinearity” error caused by a purely resistive load connected to the pot. For a general position q of the pot slider arm, suppose that the resistance in the output (pick-off) segment of the coil is Rq. Note that, assuming a uniform coil,