Strain Gages

Strain Gages

Many types of force/torque sensors are based on strain gage measurements. Although strain gages measure strain, the measurements can be directly related to stress and force. Hence, it is appropriate to discuss strain gages under force/torque sensors. Note, however, that strain gages may be used in a somewhat indirect manner (using auxiliary front-end elements) to measure other types of variables, including displacement, acceleration, pressure, and temperature. Two common types of resistance strain gages will be discussed next. Specific types

of force/torque sensors will be studied in the subsequent sections.

Equations for Strain Gage Measurements

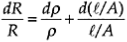

The change of electrical resistance in material when mechanically deformed, is the property used in resistance type strain gages. The resistance R of a conductor that has length l and area of cross-section A is given by

The change in resistance of a strain gage element, which determines the associated strain (Equation 6.75), is measured using a suitable electrical circuit. Many variables—including displacement, acceleration, pressure, temperature, liquid level, stress, force, and torque—can be determined using strain measurements.

Some variables (e.g., stress, force, and torque) can be determined by measuring the strain of the dynamic object itself at suitable locations. In other situations, an auxiliary front-end device may be required to convert the measurand into a proportional strain. For instance, pressure or displacement may be measured by converting them to a measurable strain using a diaphragm, bellows, or bending element.

Acceleration may be measured by first converting it into an inertia force of a suitable mass (seismic) element, then subjecting a cantilever (strain member) to that inertia force and, finally, measuring the strain at a high-sensitivity location of the cantilever element. Temperature may be measured by measuring the thermal expansion or deformation in a bimetallic element.

Thermistors are temperature sensors made of semiconductor material whose resistance changes with temperature. Resistance temperature detectors (RTDs) operate by the same principle, except that they are made of metals, not of semiconductor material.

These temperature sensors, and the piezoelectric sensors discussed previously, should not be confused with strain gages. Resistance strain gages are based on resistance change due to strain, or the piezoresistive property of materials.