Design Phase

Introduction:

Designing phase is the basic phase of management system in which new product is being designed andin “improvement phase” refers to the situation in which an existing system is being improved.

Improvement and design phase:

I. The phrase “improvement phase” refers to the situation in which an existing system is being improved.

II. The phrase “design phase” refers to the case in which a new product is being designed.

III. The recommendations derived from the improve or design phases are generally considered tentative. This follows because usually the associated performance improvements must be confirmed or verified before the associated standard operating procedures (SOPs) or design guidelines are changed or written.

IV. The term “formality” refers to the level of emphasis placed on data and/or computer assistance in decision-making.

V. In cases where a substantial amount of data is available and there are a large number of potential options, people sometimes use a high level of formality and computer assistance.

VI. In other cases, less information is available and/or a high degree of subjectivity is preferred.

VII. Then “informal” describes the relevant decision-making style. In general, statistical methods and six sigma are associated with relatively high levels of formality.

VIII. The level of formality associated with DOE-supported decision-making is generally considered to be relatively high.

IX. This section begins with a discussion of informal decision-making including so-called “seat-of-the-pants” judgments. Next, moderately formal decision making is presented, supported by so-called “QFD House of Quality,” which combines the results of benchmarking and C&E matrix method applications.

X. Finally, relatively formal “optimization” and “operations research” approaches are briefly described.

Informal Optimization:

It is perhaps true that the majority of human decisions are made informally. It is also true that formality in decision processes generally costs money and time and may not result in improved decisions.

The main goals of optimization are to make available to users relatively formal methods to support decision-making and to encourage people to use these methods.

With continual increases in competitive pressures in the business world, thorough investigation of options and consideration of various issues can be necessary to achieve profits and/or avoid bankruptcy.

Also, approximately 60% of projects showed profits, average per project profits exceeded $140,000, and some showed extremely high profits.

The degree of formality varies among informal methods.

The phrase “anecdotal information” refers to ideas that seem to be supported by a small number of stories, some of which might be factual.

“Seat-of-the-pants” decision making uses subjective judgments, potentially supported by anecdotal information, to propose new system inputs or designs. Recommendations from seat-of-the-pants approaches are rarely accompanied by any objective empirical conformation of improvement.

Relatively formal approaches involve subjective decision-making supported by the generation of tables or plots. For example, a cause & effects matrix might be generated and encourage the addition of new features to a software product design.

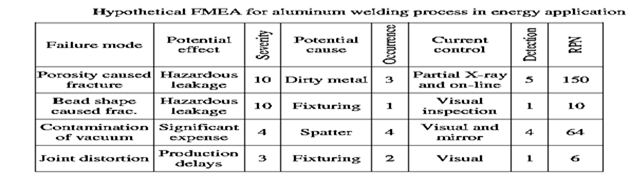

Example (High Vacuum Aluminum Welds) at one energy company, dangerous substances are stored in high vacuum aluminum tubes. The process to weld aluminum produces a non-negligible fraction of nonconforming and potentially defective welds. Develop tentativeRecommendations for process and measurement system design changes supported by the hypothetical FMEA shown in Table Assume that engineer’s rate the detection of complete X-ray inspection as a “2”.

Answer: An engineer at the energy company might look at Table and decide to implement complete inspection. This tentative choice can be written x1 = complete inspection. With this choice, fractures caused by porosity might still cause problems but they would no longer constitute the highest priority for improvement.