History Of Six Sigma

Introduction:

Six sigma is a purely management based tool, which implies on the scheduling and planning strategies by which we can improve our profit.

History of “Quality” and Six Sigma:

In this section, we briefly review the broader history of management, applied statistics, and the six sigma movement. The definition of “quality” is as obscure as the definition of six sigma. Quality is often defined imprecisely in textbooks in terms of a subjectively assessed performance level (P) of the unit in question and the expections (E) that customers have for that unit. A rough formula for quality (Q) is:

Often, quality is considered in relation to thousands of manufactured parts, and a key issue is why some fail to perform up to expectation and others succeed. It is probably more helpful to think of “quality” as a catch-word associated with management and engineering decision-making using data and methods from applied statistics. Instead of relying solely on “seat-of-the-pants” choices and the opinions of experts, people influenced by quality movements gather data and apply more disciplined methods.

History of Management and Quality

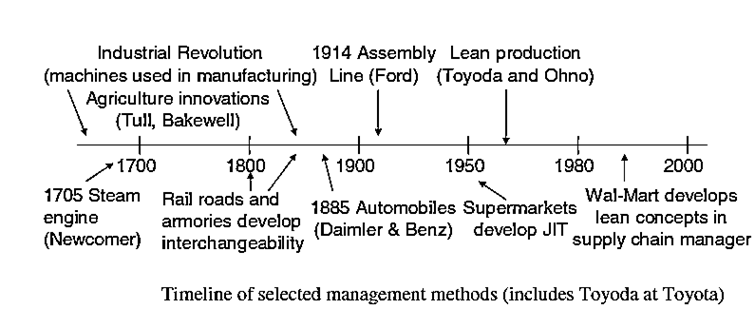

- The following history is intended to establish a context for the current quality and six sigma movements. This explanation of the history of management and quality is influenced by Womack and Jones (1996) related to so-called “Lean Thinking” and “value stream mapping” and other terms in the Toyota production system.

- In the renaissance era in Europe, fine objects including clocks and guns were developed using “craft” production. In craft production, a single skilled individual is responsible for designing, building, selling, and servicing each item. Often, a craftperson’s skills are certified and maintained by organizations called “guilds” and professional societies.

- During the 1600s and 1700s, an increasing number of goods and services were produced by machines, particularly in agriculture.

- It was not until the early 1900s that a coherent alternative to craft production of\ fine objects reached maturity. In 1914, Ford developed “Model T” cars using an “assembly line” in which many unskilled workers each provided only a small contribution to the manufacturing process.

- The term “mass production” refers to a set of management policies inspired by assembly lines. Ford used assembly lines to make large numbers of nearly identical cars. His company produced component parts that were “interchangeable” to an impressive degree. A car part could be taken from one car, put on another car, and still yield acceptable performance. As the name would imply, another trait of mass production plants is that they turn out units in large batches.

- For example, one plant might make 1000 parts of one type using a press and then change or “set up” new dies to make 1000 parts of a different type. This approach has the benefit of avoiding the costs associated with large numbers of change-overs.

-