Measurement System Analysis

Introduction:

Measurements are used to guide decisions, then it follows logically that the more error there is in the measurements, the more error there will be in the decisions based on those measurements.

Purpose

“The purpose of Measurement System Analysis is to qualify a measurement system for use by quantifying its accuracy, precision, and stability”.

- An example from industry serves to illustrate the importance of measurement system quality:

- A manufacturer of building products was struggling to improve process yields, which had a significant impact on product cost. Experience indicated that there were several process and environmental characteristics that influenced the process yield.

- Data were collected on each of the variables believed to be significant, followed by regression and correlation analysis to quantify the relationships in statistical terms.

- The results showed no clear correlation between anything - in spite of years of anecdotal evidence to the contrary! In fact, the underlying strong correlation between variables was confounded by excessive error in the measurement system.

- When the measurement systems were analyzed, many were found to exhibit error variation 2-3 times wider than the actual process spread.

- Measurements that were being used to control processes were often leading to adjustments that actually increased variation! People were doing their best, making things worse.

Characterization: A measurement system can be characterized, or described, in five ways:

Location (Average Measurement Value vs. Actual Value):

1. Stability refers to the capacity of a measurement system to produce the same values over time when measuring the same sample. As with statistical process control charts, stability means the absence of "Special Cause Variation", leaving only "Common Cause Variation" (random variation).

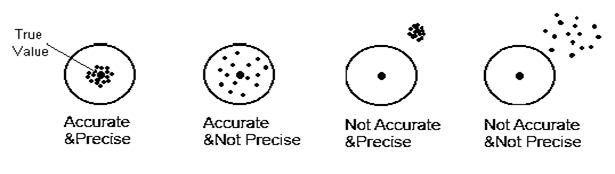

2. Bias, also referred to as Accuracy, is a measure of the distance between the average value of the measurements and the "True" or "Actual" value of the sample or part. See the illustration below for further explanation.

3. Linearity is a measure of the consistency of Bias over the range of the measurement device. For example, if a bathroom scale is under by 1.0 pound when measuring a 150 pound person, but is off by 5.0 pounds when measuring a 200 pound person, the scale Bias is non-linear in the sense that the degree of Bias changes over the range of use.

Variation (Spread of Measurement Values - Precision):

Repeatability assesses whether the same appraiser can measure the same part/sample multiple times with the same measurement device and get the same value.

Reproducibility assesses whether different appraisers can measure the same part/sample with the same measurement device and get the same value.

The diagram below illustrates the difference between the terms "Accuracy" and "Precision": Efforts to improve measurement system quality are aimed at improving both accuracy and precision.