Process Mapping

Process Mapping

1. Whereas the SIPOC is a linear flow of steps, process mapping is a tool of displaying the relationship between process steps and allows for the display of various aspects of the process, including delays, decisions, measurements, and rework and decision loops.

2. Process mapping builds on the SIPOC information by using standard symbols to depict varying aspects of the processes flow linked together with lines that include arrows demonstrating the direction of flow.

Value Stream Mapping:

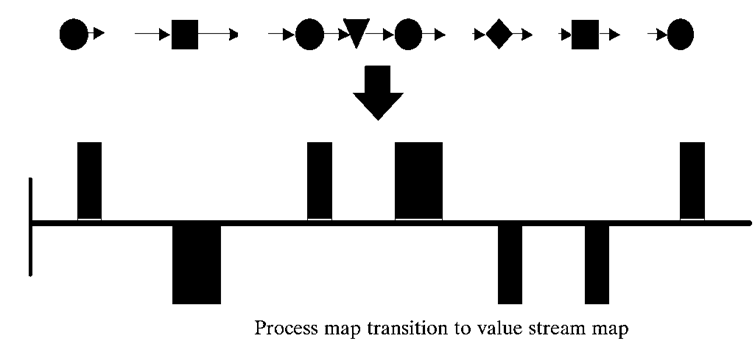

1. Process mapping can be used to develop a value stream map to understand how well a process is performing in terms of value and flow.

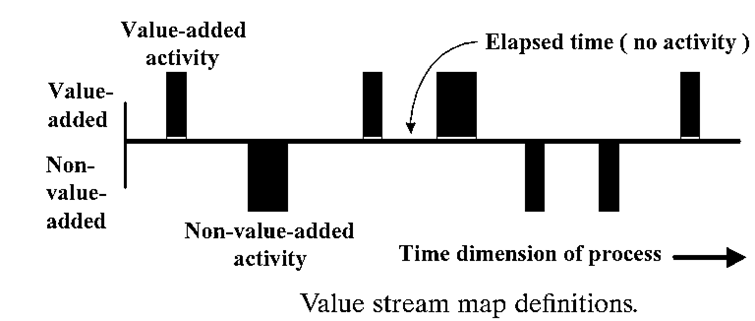

2. Value stream maps can be performed at two levels. One can be applied directly to the process map by evaluating each step of the process map as value-added or non-value-added.

3. This type of analysis has been in existence since at least the early 1980s; a good reference is the book Hunters and the Hunted (Swartz, 1996).This is effective if the design team is operating at a local level.

4. if the design team is at more of an enterprise level and needs to be concerned about the flow of information as well as the flow of product or service, a higher level value stream map is needed .