←

Six Sigma

Statistical Charting

Introduction :The measure phase in six sigma for improvement projects quantitatively evaluates the current or default system KIVs, using thorough measurements of key output variables (KOVs) before changes are made. This information aids in evaluating effects of project-related changes and assuring that the project team is not harming the system.

Types of Gauge R&R Methods:

- In all gauge R&R problems, the entities to be inspected do not need to be manufactured parts. They can be as diverse as accounting-related data or service stations. As a convenient example, however, the following sections describe the

- methods in relation to inspecting manufactured units or parts. In this chapter, two types of gauge R&R methods are described in detail: “comparison with standards” and gauge R&R (crossed). The phrase “destructive testing” refers to the process

- of measuring units such that the units cannot be measured again. The phrase “nondestructive evaluation” (NDE) refers to all other types of testing.

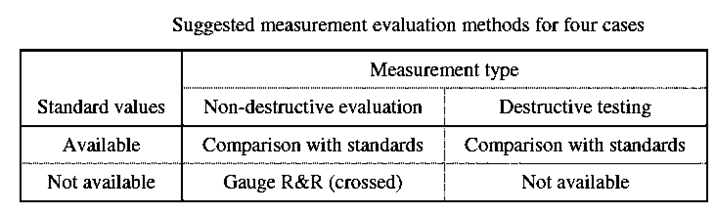

By definition gauge R&R (crossed) requires multiple measurements of each unit with different measurement systems. Therefore, this method cannot be applied in cases involving destructive sampling. Similarly, the comparison with standards method requires the availability of a standard.

εmeasurement= εrepeatability εreproducibility εsystematic

- It is apparent from that gauge R&R (crossed) should be used only when standard values are not available. To understand this, a few definitions may be helpful.

- First, “repeatability error” (εrepeatability) refers to the difference between a given observation and the average a measurement system would obtain through many repetitions.

- Second, “reproducibility error” (εreproducibility) is the difference between an average obtained by a relevant measurement system and the average obtained by all other similar systems (perhaps involving multiple people or equipment of similar type). In general, we will call a specific measurement system an “appraiser” although it might not be a person.

- Here, an appraiser could be a consulting company, or a computer program, or anything else that assigns a number to a system output.

- Third, the phrase “systematic errors” (εsystematic) refers in this book to the difference between the average measured by all similar systems for a unit and that unit’s standard value. Note that in this book, reproducibility is not considered a systematic error, although other books may present that interpretation. Writing the measurement error as εmeasurement, the following equation follows directly from these definitions:

- Without using standard values, it is logically impossible to evaluate the

- “Systematic” errors, i.e., those errors intrinsically associated with a given type of measurement system. Since gauge (crossed) does not use standard values, it can be regarded as a second-choice method. However, it is also usable in cases in which standard values are not available.

- Another method called “gauge R&R (nested)” is omitted here for the sake of brevity. Gauge R&R (nested) is relevant for situations in which the same units cannot be tested by multiple measurement systems, e.g., parts cannot be shipped to different testers.

- Gauge R&R (nested) cannot evaluate either systematic errors or the separate effects of repeatability and reproducibility errors. Therefore, it can be regarded as a “third choice” method. Information about gauge R&R (nested) is available in standard software packages such as Minitab® and in other references (Montgomery and Runger 1994).