←

Total Quality Management (TQM)

Costs And Benefits Of Tpm

Introduction:

It appears that maintenance costing has always been conducted in a cavalier manner without real effort in trying to incorporate all costing aspects. The various costs of maintenance can be represented by a curve.

Conclusions of the survey:

A survey conducted by the Department of Trade and Industry (DTI) in the UK to establish best practice in relation to maintenance, has come up with the following conclusions:

- Maintenance is not always considered at company executive level;

- Most companies seem to ignore the real cost of downtime in terms of lost sales opportunities;

- Within manufacturing industry, only 3.7% of annual sales revenue is spent on maintenance of operations equipment;

- The survey has also concluded that with good maintenance management the above costs can be drastically reduced and plant availability can be increased to lead to up to 30% increase in profitability.

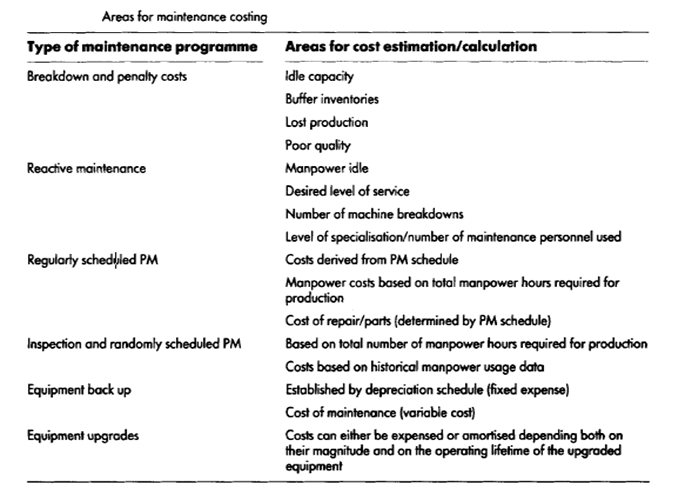

Areas for maintenance costing:

Classification of the impact of TPM on productivity levels:

The impact of TPM on productivity levels can therefore be classified both at a tactical/operational level and at the strategic level:

- At the tactical level, optimization of resources/assets leads to optimum productivity levels;

- At the strategic level, the provision of a flexible, stable, efficient and reliable manufacturing facility means that market-driven demand can be met and satisfied all the time.