Customer-supplier Chains: An Extended Model

Introduction:

Suppliers of technological systems tend to test performance of their processes by using a range of materials/components known to them and which are available in the market place. This may inhibit process flexibility if they have not taken into account materials being developed in the future. The extended customer-supplier model suggests that both suppliers of process equipment have to work much more closely together, if they have developed long term partnerships with the same customer.

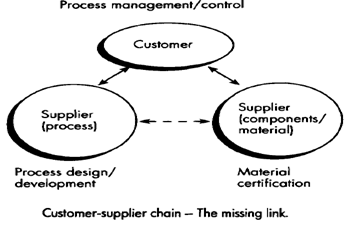

Customer-supplier chain - The missing link

- Suppliers of raw materials/components may use process equipment which may not be compatible with that of their customers or which may cease to become compatible if customers decide to upgrade their process equipment.

- This has been reported many times, for example suppliers of plastics injection molding machinery do not take into account the latest developed polymers or suppliers of tooling do not take into account the type of machine tools customers are using.

- The problems which can occur restrict the flexibility of the customer and may even limit process capability and mislead customers into investigating for random or systematic causes of variation, if they have not been made aware that the process equipment capability has not previously been tested for new raw materials/ components.

- There is therefore a missing link for the perfect customer-supplier chain

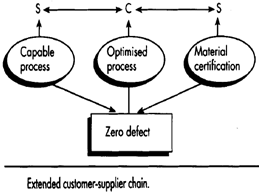

Extended customer-supplier chain

- The extended customer-supplier model suggests that both suppliers of process equipment have to work much more closely together, if they have developed long term partnerships with the same customer.

- This is thought to be necessary if the concept of Zero Defect is to be achieved. Both types of suppliers can benefit from such a relationship.

- By gaining access to privileged information on future customer intentions in relation to capital investment, suppliers of process equipment may get involved as early as possible with the customer to design, manufacture, and test and implement the equipment desired.

- Suppliers of raw material components on the other hand may decide to work closely with the supplier of technological equipment on existing and new products so that process capability is determined before the implementation programme starts.

Extended customer-supplier chains mean that total compatibility and synchronization is achieved all the time with benefits to all parties concerned.