How Do We Define Processes?

Introduction:

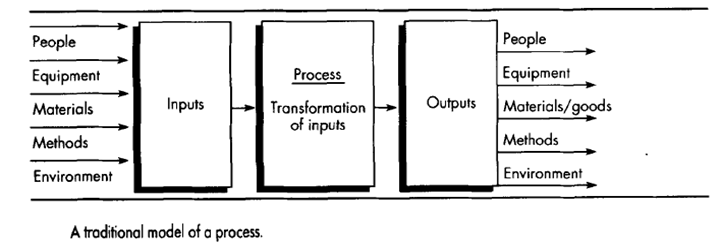

Traditionally, processes have been defined as series of transformations of inputs into outputs. The key characteristics of this description of a process are that transformation means adding creating value in one of three forms.

Model of the process:

- Time value: Products services are provided when required;

- Place value: Products/services are provided where required;

- Form value: Products services are provided how required.

This traditional view of ‘a process’ has got many shortcomings however. It fails to identify, amongst others, the following key points:

1. How can a typical process be determined?

2. Where the value does added activity start and where does it finish?

3. Where does process management and control take place?

Process documentation:

Each activity (process) has to be properly documented to include the following:

- Process ownership should be clearly defined with responsibility for improvement

- Boundaries for each process should be clearly identifiable;

- The flow of each process has to be well understood;

- Process objectives should be clearly identified;

- Process performances should be measured against its objectives;

- Process performance measures should be checked for validity already determined;

Process documentation by answering the above questions is vital if organisations are to achieve superior performance based on TQM philosophy. This effort (documentation) will reflect three main points:

- That strengths and weaknesses of the organisation are well understood. This

- That control over activities is tight, since process ownership responsibility has

- That performance measurement is a distributed activity thus reflecting the overall means that competitive objectives are realistic and tangible; been allocated throughout the organisation; effort in adding value.

Process improvement:

‘Process improvement is the continuous endeavor to learn about the cause-and-effect mechanisms in a process to change the process to reduce variation and complexity and improve customer satisfaction. Improvements are made through actions that are based on a better understanding of the cause system that affects process performance.’