Tqm Implementation

Introduction:

Some gurus place too much emphasis on technical processes and some concentrate more on people/management issues. For example Crosby’s approach is based on the four absolutes of quality management (conformance to requirements, the system for causing quality is prevention not appraisal, the performance standard is Zero Defect, the measurement of quality is the price of non-conformance). Crosby insists that there has to be a clear policy, through training of the workforce and management and commitment through what he calls ‘executive witness.

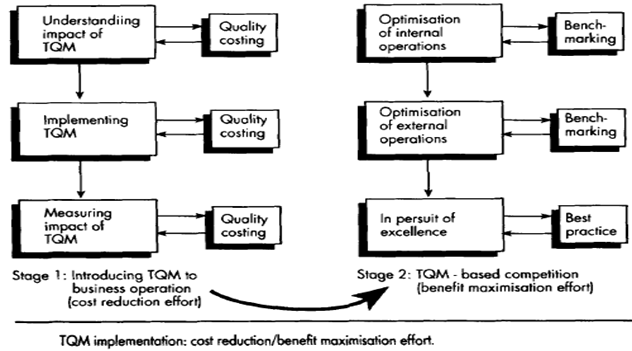

TQM implementation: cost reduction/benefit maximization effort:

- Deming and Juran however place more emphasis on the process;

- They believe that Zero Defect can only be achieved by continuous improvement as a never-ending activity.

- They argue that Zero Defect as a slogan can demotivate people, particularly if they are not provided with explanations on how to achieve it. The Crosby approach does not explain how to achieve Zero Defect.

At the heart of the model is the establishment of customer-supplier chains where the interplay of supplier and customer processes determines the strategy for continuous improvement, through process feedback and customer feedback.

There are thirteen steps in the Oakland approach to TQM implementation as follows:

- Understanding quality;

- Commitment to quality;

- Policy on quality;

- Organisation for quality;

- Measurement costs of quality;

- Planning for quality;

- Design for quality;

- System for quality;

- Capability for quality;

- Control for quality;

- Team work for quality;

- Training for quality;

- Implementation of TQM.

The thirteen stages represent a gradual progression towards implementing a TQM based culture.