←

Automobile Engineering

Basic Control Switches

Introduction:

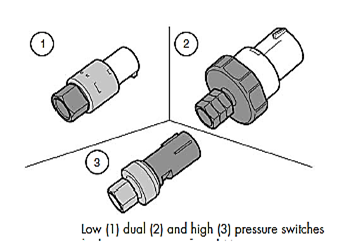

There are three basic types of control switches. These are low, dual and high pressure switches. Pressure sensors and Trinary switch are also used.

Pressure switching devices

Low pressure switch

- Reacts to the pressure in the low side (suction side) of the system, generally the accumulator and disengages the compressor clutch if the pressure drops below approximately 1.5 bar.

- On an FOV system the low pressure switch and cycling switch are often the same device.

Dual pressure – high pressure switch and condenser fan switch

- Two pressure-sensitive switches are contained in the high pressure switch. One of these switches acts as a safety switch to prevent excessive system pressure.

- The second switch switches the condenser auxiliary fan on to its second setting at approximately 20.7 bar and off again at 17.2 bar.

- This switching process improves the performance of the system in cases of excessive heat.

High pressure switch

A single normally closed pressure switch de-energises the compressor if excessive high pressure exists within the A/C system, approximately 30–35 bar. The switch is normally positioned in the high side of the system.

Trinary switch

- Three pressure sensitive switches are integrated into a trinary switch. A low pressure switch which creates an open circuit thus removing the current flowing to the compressor if the system pressure drops below approximately 1.4 bar. This could be caused by a refrigerant leak or natural discharge over a number of years.

- A high pressure switch operates at a pressure of approximately 30 bar which again removes the A/C compressor’s current in the event of a system blockage anywhere in the system.

- The third switch is used for high speed operation of the condenser fan aiding the removal of heat. This operates at approximately 18 bar. The switch is positioned on the high pressure side on TXV controlled systems.

- If FOV is used then a cycling switch is incorporated into the low side with a dual pressure switch on the high side. Modern A/C systems are replacing switches with a single pressure sensor.

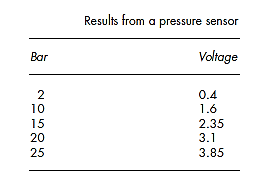

Pressure sensors

- The pressure sensor contains two metal plated ceramic discs mounted in close proximity. The disc located closest to the pressure connection is thinner and bends when subjected to pressure.

- By this means, capacitance between the metal plating of the discs is changed based on the pressure. A circuit integrated in the sensor converts the capacitance to an analogue voltage.