←

Automobile Engineering

Preventive Maintenance

Introduction:

There are many definitions of preventive maintenance, but all preventive maintenance management programs are time-driven. In other words, maintenance tasks are based on elapsed time or hours of operation.

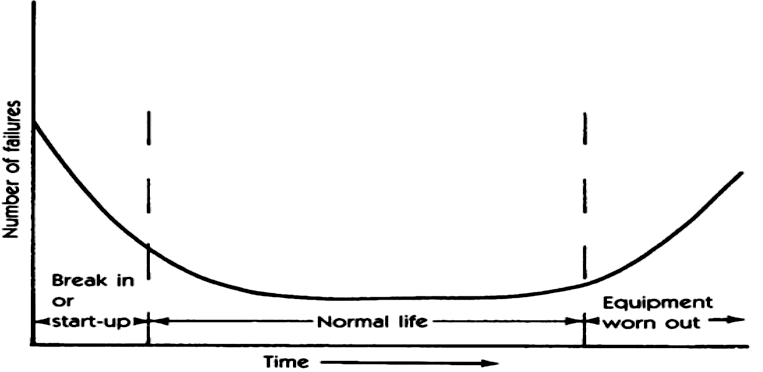

BATHTUB CURVE:

- The mean-time-to-failure (MTTF) or bathtub curve indicates that a new machine has a high probability of failure because of installation problems during the first few weeks of operation.

- After this initial period, the probability of failure is relatively low for an extended period.

- After this normal machine life period, the probability of failure increases sharply with elapsed time.

- In preventive maintenance management, machine repairs or rebuilds are scheduled based on the MTTF statistic.

The actual implementation of preventive maintenance varies greatly. Some programs are extremely limited and consist of only lubrication and minor adjustments. Comprehensive preventive maintenance programs schedule repairs, lubrication, adjustments, and machine rebuilds for all critical plant machinery. The common denominator for all of these preventive maintenance programs is the scheduling guideline—time.

- All preventive maintenance management programs assume that machines will degrade within a time frame typical of their particular classification.

- For example, a single stage, horizontal split-case centrifugal pump will normally run 18 months before it must be rebuilt. Using preventive management techniques, the pump would be removed from service and rebuilt after 17 months of operation.

- The problem with this approach is that the mode of operation and system or plant-specific variables directly affects the normal operating life of machinery.

- The mean-time-between-failures (MTBF) is not the same for a pump that handles water and one that handles abrasive slurries.

- The normal result of using MTBF statistics to schedule maintenance is either unnecessary repairs or catastrophic failure. In the example, the pump may not need to be rebuilt after 17 months.

- Therefore, the labor and material used to make the repair was wasted. The second option using preventive maintenance is even more costly. If the pump fails before 17 months, it must be repaired using run-to-failure techniques.