Diesel Fuel Injection Systems

Introduction:

The high temperature needed to ignite fuel in a diesel engine is obtained by high compression of the air charge. Diesel engines have the fuel injected into the combustion chamber where it is ignited by heat in the air charge. This is known as compression ignition (CI) because no spark is required.

Injection in diesel engine:

- The high temperature needed to ignite the fuel is obtained by a high compression of the air charge.

- Diesel fuel is injected under high pressure from an injector nozzle, into the combustion chambers.

- The fuel is pressurized in a diesel injection pump. It is supplied and distributed to the injectors through high-pressure fuel pipes or directly from a rail and/or an injector.

- The high pressure is generated from a direct acting cam or a separate pump. The air flow into a diesel engine is usually unobstructed by a throttle plate so a large air charge is always provided.

- Throttle plates may be used to provide control for emission devices. Engine speed is controlled by the amount of fuel injected.

- The engine is stopped by cutting off the fuel delivery. For all engine operating conditions a surplus amount of air is needed for complete combustion of the fuel.

- Small high-speed diesel engine compression ratios are about 20:1 for direct injection systems.

- This compression ratio is capable of raising the air charge to temperatures of between 500°C and 800°C. Very rapid combustion of the fuel therefore occurs when it is injected into the hot air charge.

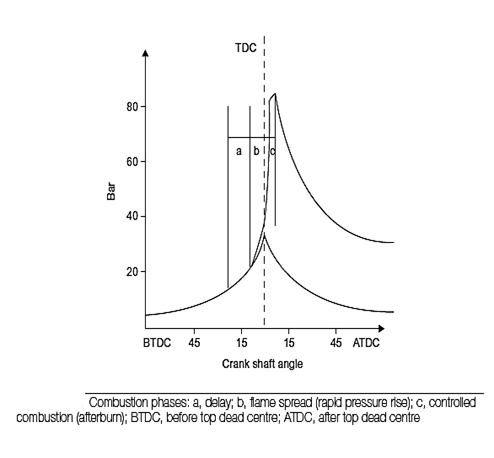

- The combustion process in a diesel engine follows three phases: ignition delay, flame spread and controlled combustion. In addition, an injection lag occurs in the high-pressure pipes of earlier systems, as the pressure builds up just before injection.

- The most important phase of controlled combustion is when fuel is being injected into a burning mixture.

- This must be at a rate that maintains an even combustion pressure onto the piston throughout the critical crankshaft rotational angles.

- This gives maximum torque and efficient fuel usage, because temperatures remain controlled and the heat lost to the exhaust is minimized. The low temperatures also help to keep NO x emissions to a minimum.

The delay phase or ignition lag for diesel fuel combustion lasts a few milliseconds. It occurs immediately on injection as the fuel is heated up to the self-ignition temperature. The length of the delay is dependent on the compressed air charge temperature and the grade of fuel. The air charge temperature is also affected by the intake air temperature and the engine temperature. A long delay period allows a high volume of fuel to be injected before ignition and flame spread occurs. In this situation diesel knock is at its most severe. When a diesel engine is cold, there may be insufficient heat in the air charge to bring the fuel up to the self-ignition temperature. When ignition is slow, heavy knocking occurs.