Gasoline Direct Injection

Introduction:

Bosch’s high-pressure injection system for petrol engines is based on a pressure reservoir and a fuel rail, which a high-pressure pump charges to a regulated pressure of up to 120 bar. The fuel can therefore be injected directly into the combustion chamber via electromagnetic injectors.

Gasoline direct injection on an engine

- The air mass drawn in is adjusted through an electronically controlled throttle valve and is measured with the help of an air mass meter.

- For mixture control, a wide-band oxygen sensor is used in the exhaust, before the catalytic converters.

- This sensor can measure a range between

λ =0.8 and infinity.

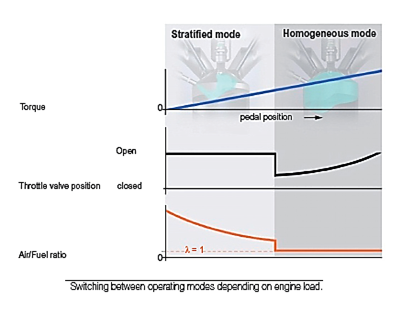

- The electronic engine control unit regulates the operating modes of the engine with gasoline direct injection in three ways:

● stratified charge operation – with λ values greater than 1

● homogeneous operation – at λ =1

● rich homogeneous operation – with λ =0.8.

Compared to the traditional manifold injection system, the entire fuel amount must be injected in full-load operation in a quarter of the time. The available time is significantly shorter during stratified charge operation in part-load. Especially at idle, injection times of less than 0.5 milliseconds are required owing to the lower fuel consumption. This is only one-fifth of the available time for manifold injection.

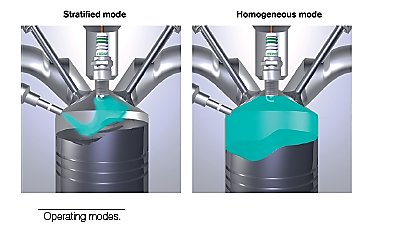

- Fuel injection just before the ignition point and injection directly into the combustion chamber is to create a stratified (layered) mode.

- The result is a combustible air/fuel mixture cloud on the spark plug, cushioned in a thermally insulated layer, composed of air and residual gas.

- This raises the efficiency level because heat loss is avoided on the combustion chamber walls.

- The engine operates with an almost completely opened throttle valve, which avoids additional charge losses.

- With stratified charge operation, the lambda value in the combustion chamber is between about 1.5 and 3.

- In the part-load range, gasoline direct injection achieves the greatest fuel savings, with up to 40% at idle compared to conventional petrol injection processes.

- With increasing engine load, and therefore increasing injection quantities, the stratified charge cloud becomes even richer and emission characteristics become worse.

- As in diesel engine combustion, soot may form. In order to prevent this, the DI-Motronic engine control converts to a homogeneous cylinder charge at a predefined engine load.

- The system injects very early during the intake process to achieve a good mixture of fuel and air at a ratio of

λ =1.