←

Automobile Engineering

Lubrication System

Introduction:

There are various parts in lubrication system like sump reservoir, plunger and spring etc.

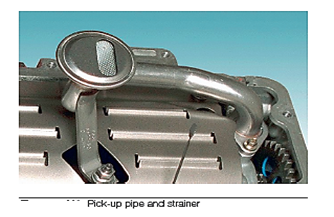

Pick-up pipe and strainer

- From the sump reservoir under the crankshaft oil is drawn through a strainer into the pump.

- Oil pumps have an output of tens of litres per minute and operating pressures of over 5 kg/cm 2 at high speeds.

Pressure relief valve

- Pressure relief valve limits the pressure of the lubrication system to between 2.5 and 4 kg/cm 2.

- The pressure relief valve is a spring-loaded conical, or ball, valve that opens when the pressure in the oil exceeds the spring force acting on the valve seat.

- When the valve opens, a return drilling is uncovered and the excess oil flows through this to return to the sump.

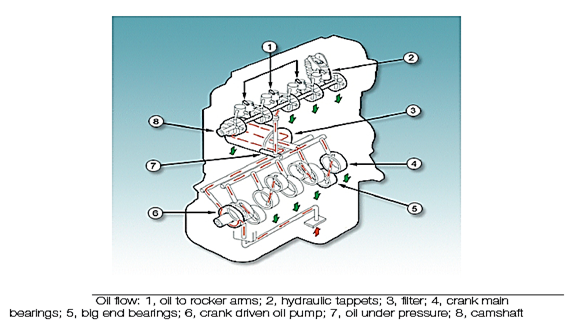

- This control is needed because the pump would produce excessive pressure at high speeds. After leaving the pump, oil passes into a filter and then into a main oil gallery in the engine block or crankcase

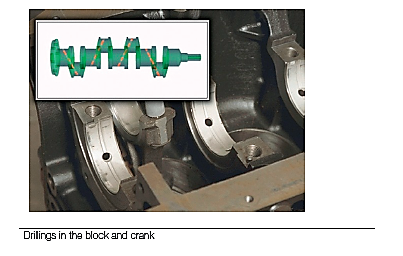

- Drillings connect the gallery to the crankshaft bearing housings and when the engine is running, oil is forced under pressure between the rotating crank journals and the main bearings.

- The crankshaft is drilled so that the oil supply from the main bearings is also to the big-end bearing bases of the connecting rods.

- The connecting rods are often drilled near the base so that a jet of oil sprays the cylinder walls and the underside of the pistons