Pressure Gauge Readings

Introduction

Pressure gauges are essential instruments used in various fields, including automobile engineering, to measure and monitor pressure levels within systems. Accurate pressure readings are crucial for ensuring the proper functioning, safety, and efficiency of equipment. This chapter explores the types of pressure gauges, how to read them, and their applications in automobile systems.

Types of Pressure Gauges

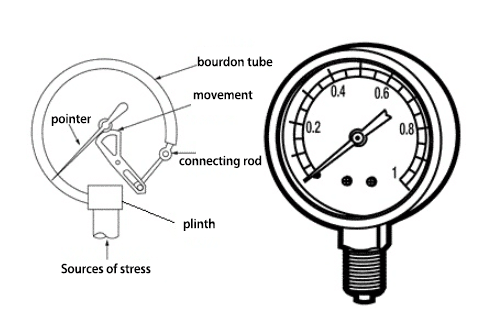

1. Bourdon Tube Gauge

The Bourdon tube gauge is one of the most common types of pressure gauges. It consists of a curved, flattened tube that straightens as pressure increases, causing a needle to move on a dial.

Figure : Bourdon Tube Gauge

Key Features:

- Range: Typically 0 to 100 psi or more

- Accuracy: ±1% to ±2% of full scale

- Applications: Used in various industrial and automotive applications

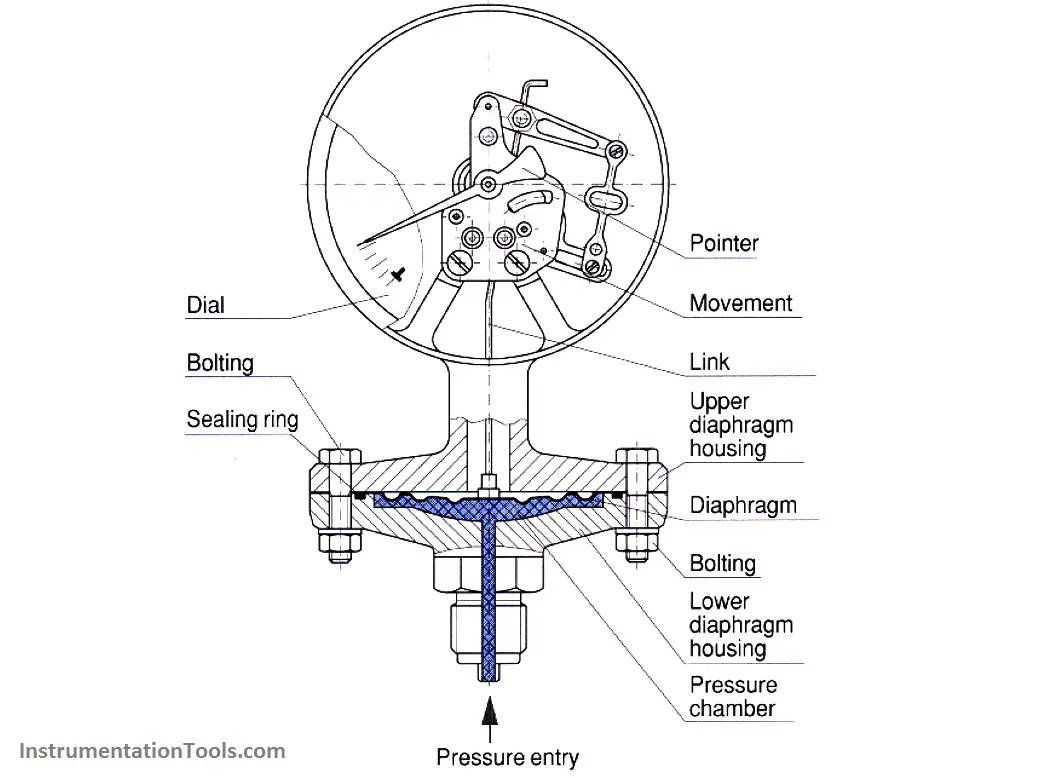

2. Diaphragm Gauge

Diaphragm gauges use a flexible diaphragm that deflects under pressure. The deflection is converted into a reading on the gauge.

Figure: Diaphragm Gauge

Key Features:

- Range: Can measure low to medium pressures

- Accuracy: Varies by design, generally high accuracy

- Applications: Suitable for measuring pressures in gases and liquids

3. Digital Pressure Gauge

Digital pressure gauges provide a digital readout of pressure values, often with additional features such as data logging and calibration alerts.

Figure: Digital Pressure Gauge

Key Features:

- Range: Varies widely based on model

- Accuracy: High precision, often ±0.1% of full scale

- Applications: Used in precision engineering, automotive diagnostics, and laboratory settings

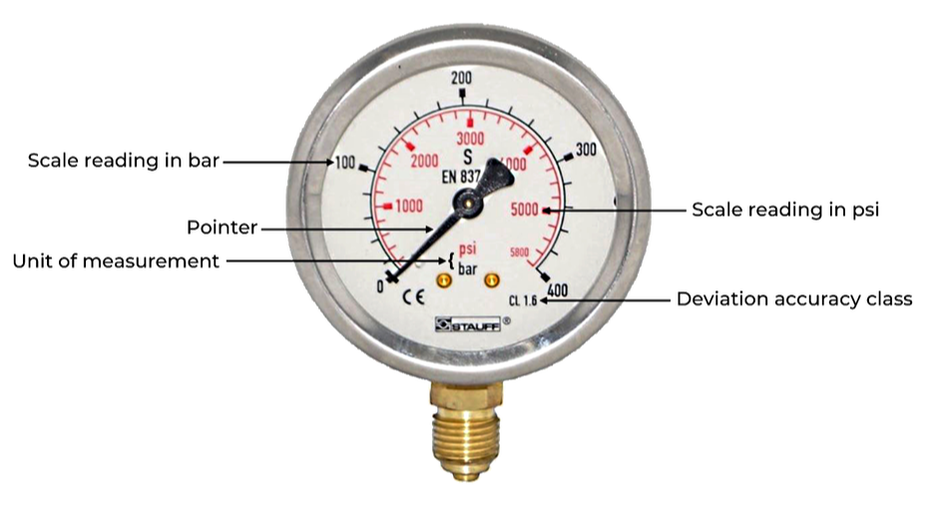

Reading Pressure Gauges

Reading pressure gauges accurately requires understanding the gauge's scale and the units of measurement. Here's a step-by-step guide:

1. Identify the Scale

Different gauges may use various scales (e.g., psi, bar, kPa). Ensure you are reading the scale that matches your requirements.

2. Read the Needle Position

For analog gauges, locate the needle's position on the scale. The needle indicates the pressure value directly.

3. Note the Units

Pressure values are measured in various units. Common units include:

- psi (pounds per square inch)

- bar

- kPa (kilopascals)

4. Check Calibration

Ensure the gauge is calibrated correctly. If it’s an older gauge or has been subject to harsh conditions, recalibration might be necessary.

Figure: How to Read a Pressure Gauge

Applications in Automobile Engineering

Pressure gauges play a critical role in various automotive systems:

1. Tire Pressure Monitoring

Regularly checking tire pressure ensures safety, fuel efficiency, and optimal tire performance. Accurate readings prevent issues such as blowouts and uneven wear.

2. Engine Oil Pressure

Monitoring engine oil pressure helps ensure that the engine is properly lubricated. Low oil pressure can indicate potential problems such as leaks or oil pump failure.

3. Fuel System Pressure

In fuel systems, maintaining the correct pressure is crucial for optimal engine performance. Pressure gauges can help diagnose fuel delivery issues.

4. Cooling System Pressure

Cooling system pressure gauges help monitor the pressure in the radiator and other cooling components. Proper pressure ensures effective cooling and prevents overheating.

Best Practices

1. Regular Calibration

Ensure pressure gauges are regularly calibrated to maintain accuracy. Calibration should be performed according to the manufacturer’s recommendations.

2. Proper Installation

Install gauges correctly to avoid mechanical damage and ensure accurate readings. Use appropriate fittings and avoid over-tightening.

3. Maintenance and Care

Keep gauges clean and free from debris. Regularly inspect for signs of wear or damage and replace faulty gauges as needed.

4. Data Interpretation

Accurate data interpretation requires understanding normal operating pressure ranges for various systems. Consult vehicle manuals or system specifications for reference.

Conclusion

Pressure gauges are vital tools in automobile engineering and other fields, providing critical data for maintaining equipment performance and safety. Understanding how to read and interpret pressure gauge readings accurately is essential for effective maintenance and troubleshooting. Proper use and regular calibration of pressure gauges ensure reliable measurements and optimal operation of systems.