The Development Of The Automobile As A Mechatronic System

The Development of the Automobile as a Mechatronic System

The evolution of modern mechatronics can be illustrated with the example of the automobile. Until the 1960s, the radio was the only significant electronics in an automobile.

All other functions were entirely mechanical or electrical, such as the starter motor and the battery charging systems. There were no “intelligent safety systems,” except augmenting the bumper and structural members to protect occupants in case of accidents.

Seat belts, introduced in the early 1960s, were aimed at improving occupant safety and were completely mechanically actuated.

All engine systems were controlled by the driver and/or other mechanical control systems. For instance, before the introduction of sensors and microcontrollers, a mechanical distributor was used to select the specific spark plug to fire when the fuel–air mixture was compressed.

The timing of the ignition was the control variable. The mechanically controlled combustion process was not optimal in terms of fuel efficiency. Modeling of the combustion process showed that, for increased fuel efficiency, there existed an optimal time when the fuel should be ignited.

The timing depends on load, speed, and other measurable quantities. The electronic ignition system was one of the first mechatronic systems to be introduced in the automobile in the late 1970s.

The electronic ignition system consists of a crankshaft position sensor, camshaft position sensor, airflow rate, throttle position, rate of throttle position change sensors, and a dedicated microcontroller determining the timing of the spark plug firings. Early implementations involved only a Hall Effect sensor to sense the position of the rotor in the distributor accurately. Subsequent implementations eliminated the distributor completely and directly controlled the firings utilizing a microprocessor.

Mechatronics has become a necessity for product differentiation in automobiles.

Since the basics of internal combustion engine were worked out almost a century ago, differences in the engine design among the various automobiles are no longer useful as a product differentiator.

In the 1970s, the Japanese automakers succeeded in establishing a foothold in the U.S. automobile market by offering unsurpassed quality and fuel-efficient small automobiles.

The quality of the vehicle was the product differentiator through the 1980s. In the 1990s, consumers came to expect quality and reliability in automobiles from all manufacturers.

Today, mechatronic features have become the product differentiator in these traditionally mechanical systems. This is further accelerated by higher performance price ratio in electronics, market demand for innovative products with smart features, and the drive to reduce cost of manufacturing of existing products through redesign incorporating mechatronics elements.

With the prospects of low single digit (2–3%) growth, automotive makers will be searching for high-tech features that will differentiate their vehicles from others. The automotive electronics market in North America, now at about $20 billion, is expected to reach $28 billion by 2004.

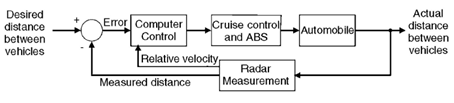

New applications of mechatronic systems in the automotive world include semi-autonomous to fully autonomous automobiles, safety enhancements, emission reduction, and other features including intelligent cruise control, and brake by wire systems eliminating the hydraulics .

Another significant growth area that would benefit from a mechatronics design approach is wireless networking of automobiles to ground stations and vehicle-to vehicle communication.

Telematics, which combines audio, hands-free cell phone, navigation, Internet connectivity, e-mail, and voice recognition, is perhaps the largest potential automotive growth area. In fact, the use of electronics in automobiles is expected to increase at an annual rate of 6% per year over the next five years, and the electronics functionality will double over the next five years.