Transmission Components

Transmission Components

Transmission devices are indispensable in mechatronic applications. We will undertake to discuss a few representative transmission devices here.

It should be cautioned that in the present treatment, a transmission is isolated and treated as a separate unit. In an actual application, however, a transmission device works as an integral unit with other components, particularly the actuator, and the electronic drive unit, and the load of the system. Hence a transmission design or selection should involve an integrated treatment of all interacting components.

Perhaps the most common transmission device is a gearbox. In its simplest form, a gearbox consists of two gear wheels, which contain teeth of identical pitch (tooth separation) and of unequal wheel diameter.

The two wheels are meshed (i.e., the teeth are engaged) at one location. This device changes the rotational speed by a specific ratio (gear ratio) as dictated by the ratio of the diameters (or radii) of the two gear wheels. In particular, by stepping down the speed (in which case the diameter of the output gear is larger than that of the input gear), the output torque can be increased.

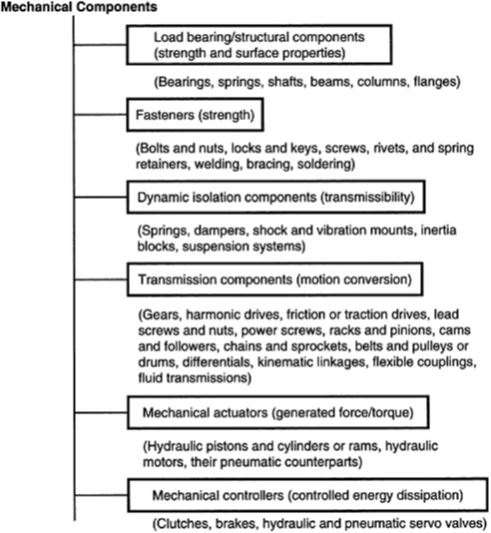

Larger gear ratios can be realized by employing more than one pair of meshed gear wheels. Gear transmissions Classification of mechanical components.

are used in a variety of applications including automotive, industrial-drive and robotics. Specific gear designs range from conventional spur gears to harmonic drives, as discussed later in the present section. Gear drives have several disadvantages. In particular, they exhibit “backlash” because the tooth width is smaller than the tooth space of the mating gear.

Some degree of backlash is necessary for proper meshing. Otherwise jamming will occur.

Unfortunately, backlash is a nonlinearity, which can cause irregular and noisy operation with brief intervals of zero torque transmission. It can lead to rapid wear and tear and even instability. The degree of backlash can be reduced by using proper profiles (shapes) for the gear teeth.

Backlash can be eliminated through the use of spring-loaded gears. Sophisticated feedback control may be used as well to reduce the effects of gear backlash.