Ways Of Integration

Introduction:

A general scheme of a classical mechanical-electronic system. Such systems resulted from adding available sensors, actuators, and analog or digital controllers to mechanical components.

The limits of this approach were given by the lack of suitable sensors and actuators, the unsatisfactory life time under rough operating conditions (acceleration, temperature, and contamination), the large space requirements, the required cables, and relatively slow data processing.

With increasing improvements in miniaturization, robustness, and computing power of microelectronic components, one can now put more emphasis on electronics in the design of a mechatronic system.

More autonomous systems can be envisioned, such as capsuled units with touchless signal transfer or bus connections, and robust microelectronics.

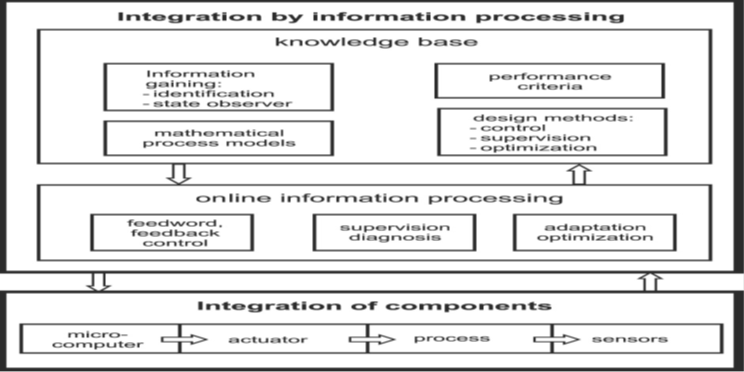

The integration within a mechatronic system can be performed through the integration of components and through the integration of information processing.

Integration of Components (Hardware)

The integration of components (hardware integration) results from designing the mechatronic system as an overall system and imbedding the sensors, actuators, and microcomputers into the mechanical process,

This spatial integration may be limited to the process and sensor, or to the process and actuator. Microcomputers can be integrated with the actuator, the process or sensor, or can be arranged at several places.

Integrated sensors and microcomputers lead to smart sensors , and integrated actuators and microcomputers lead to smart actuators . For larger systems, bus connections will replace cables.

Hence, there are several possibilities to build up an integrated overall system by proper integration of the hardware.

Integration of Information Processing (Software)

The integration of information processing (software integration) is mostly based on advanced control functions.

Besides a basic feed forward and feedback control, an additional influence may take place through the process knowledge and corresponding online information processing.

This means a processing of available signals at higher levels, including the solution of tasks like supervision

with fault diagnosis, optimization, and general process management. The respective problem solutions result in real-time algorithms which must be adapted to the mechanical process properties, expressed by mathematical models in the form of static characteristics, or differential equations. Therefore, knowledge

base is required, comprising methods for design and information gaining, process models, and performancecriteria. In this way, the mechanical parts are governed in various ways through higher levelinformation processing with intelligent properties, possibly including learning, thus forming an integration

by process-adapted software.