System Modeling

Introduction:

System modeling as a term includes two important commonly used concepts: systemand modeling. It is imperative to clarify such concepts before attempting to focus on their relevance to the “simulation” .

System Concept:

1. The word systemis commonly used in its broad meaning in a variety of engineering and non-engineering fields.

2. In simple words, a system is often referred to as a set of elements or operations that are organized and logically related toward the attainment of a certain goal or objective.

3. To attain the intended goal or to serve the desired function, it is necessary for the system to receive a set of inputs, to process them correctly, and to produce the required outcomes.

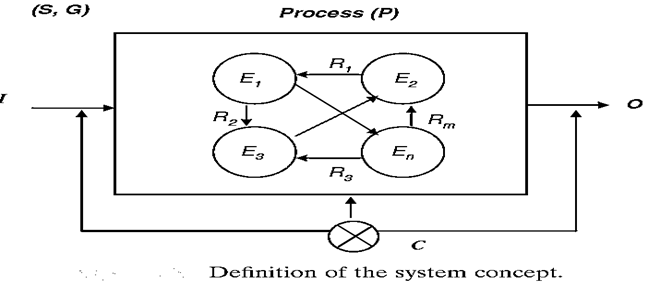

4. To sustain such flow, some control is required to govern system behavior. Given such a definition, we can analyze any system (S) based on the architecture shown in Figure below

a) As shown in the figure, each system can be defined primarily in terms of a set of inputs (I) and a process (P) that transforms and changes the characteristics of system inputs to produce a specific set of outputs (O). The process is performed through a sets of system elements (E) governed by a set of relationships (R).

b) An overall goal (G) is often defined to represent the purpose and objective of the system. To sustain a flawless flow and correct functionality of I–P–O, some type of control (C) is essentially applied to system inputs, process, and outputs.

c) Thus, building a system requires primarily six basic elements:

1) Specifying the set of inputs (I ) and the specifications required to produce specified outcomes (O).

2) Listing system elements S = (E1, E2, E3. . . En) and defining the characteristics and the individual role of each element.

3) Analyzing and understanding the logical relationships (R1, R2, R3, . . . , Rm) among the set of system elements defined.

4) Specifying the set of outcomes (O) that should be produced and their specifications in order to reach the goal (G) and objective specified.

5) Specifying the system controls (C) and their rules in monitoring and adjusting I–P–O flow to meet inputs (I ), process (P), and output (O) specifications.

6) Defining the goal (G) or the overall system objective and relating system structure (inputs, elements, relationships, controls, and outputs) to goal attainment.